(3) Procedure for deleting a registered rotor

Step

Touchscreen operation

Screen displays and notes

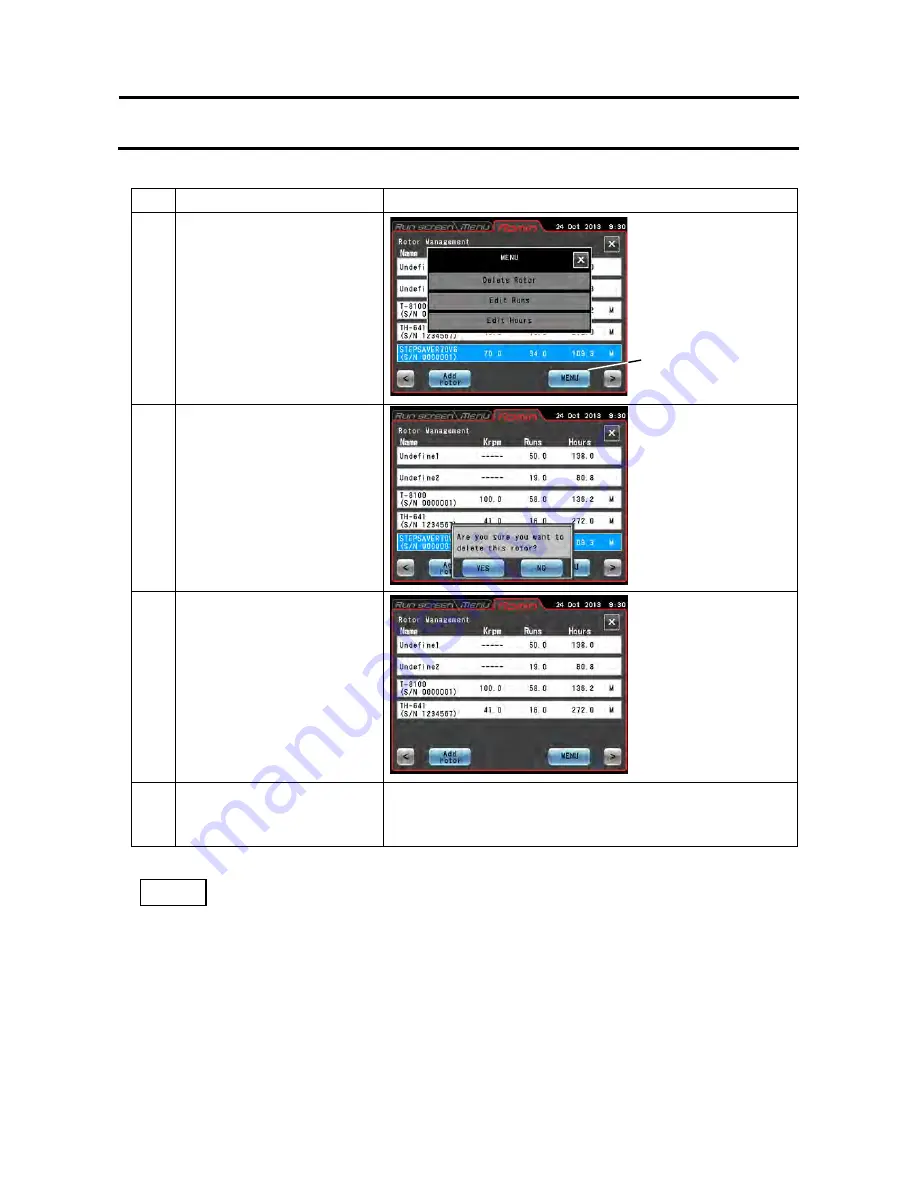

1

Press the Rotor management

button, select the rotor to

delete and press the

[MENU]

button.

2

Press the

[Delete Rotor]

button in the menu box.

3

Press the

[YES]

button in the

delete confirmation box.

4

Press the Run screen tab to

return to the Run screen.

The display again shows the Run screen.

1) Undefined 1 is the default selection that is automatically made when a rotor is installed without

selecting Undefined 2 or another rotor from the rotor list. It records the run history of all rotors

that are installed in the same way.

2) Select Undefined 2 rotor for a specific rotor whose run history you want to record without

registering it.

3) Undefined 1 rotor and undefined 2 rotor cannot be deleted.

●

The selected rotor is

deleted from the

Rotor management

screen.

●

The MENU box

appears in the Rotor

management screen.

●

A delete confirmation

message appears.

NOTE

3-4-6 Admin Function

[MENU]

button

3-97