All installations and services must be performed by qualified service personnel.

13

b. Dual pressure switch assembly MUST be relocated to the blower deck using screws/holes

provided.

c. If furnace is installed on a combustible floor, a non-combustible base must be used.

d. Pressure switch tubing to the coil outlet MUST be moved to the bottom ¼” port of the coil

outlet. On CLQS1-100T48N & CLQS1-125T60N models the 16” long tubing installed from the

factory MUST be replaced with the 20” piece provided in the parts package. Move ¼” cap to the

unused coil outlet port.

3. HORIZONTAL LEFT

a. Install plenum adapters (4) provided.

b. Aux limit on the blower housing MUST be moved to the motor side using the short bracket

pre-installed on blower housing.

c. Dual pressure switch assembly MUST be relocated to the blower deck using screws/holes

provided.

d. Pressure switch tubing to the coil outlet MUST be moved to the bottom ¼” port of the coil

outlet. On CLQS1-100T48N & CLQS1-125T60N models the 16” long tubing installed from the

factory MUST be replaced with the 20” piece provided in the parts package. Move ¼” cap to the

unused coil outlet port.

4. HORIZONTAL RIGHT

a. Install plenum adapters (4) provided.

b. Inducer MUST be removed, rotated 180° & re-installed so that vent pipe exits cabinet thru the

top.

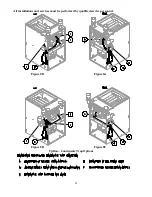

5. If inducer is to be rotated, first remove front channel into which the doors snap. Then remove inducer,

rotate 180° and reinstall. Then reinstall the front door channel being sure to align the front edge with the

front edge of the side casings. Remove yellow cap from rubber drain and move to its top port. Remove

the clear internal support from rubber drain and move to its bottom port.

6. Apply adhesive backed foam washers onto condensate tubing at the exit of the cabinet to seal the gap

created between tubing and knockout.

E. GENERAL REQUIREMENTS FOR VENTING

The furnace venting system must be installed by a qualified service person in accordance with local

installation codes and these instructions. In the absence of applicable local codes, conform to the National

Fuel Gas Code, NFPA 54 /ANSI Z223.1-2002, or latest edition thereof.

Provide adequate combustion and ventilation air to the furnace space as specified in Section III parts D

through H.

Summary of Contents for CLQS1-050T36N

Page 2: ......

Page 4: ......

Page 47: ...All installations and services must be performed by qualified service personnel 45...

Page 55: ...All installations and services must be performed by qualified service personnel 53...

Page 56: ...All installations and services must be performed by qualified service personnel 54...

Page 57: ...All installations and services must be performed by qualified service personnel 55...

Page 59: ...All installations and services must be performed by qualified service personnel 57...

Page 60: ...All installations and services must be performed by qualified service personnel 58...