All installations and services must be performed by qualified service personnel.

32

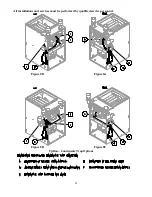

the cabinet. Attach the barb elbow to end of tube “A” and attach a piece of clear flexible tubing to the

barb, leading to the drain trap.

c. Attach clear flexible tubing from rubber drain at the exit of the inducer thru the cabinet to the drain

trap.

NOTICE:

Condensate trap must be installed at least 2-1/2” below furnace.

6. Additional Requirements

Apply adhesive backed foam washers onto condensate tubing at the exit of the cabinet to seal the gap

created between tubing and knockout.

If the condensate trap is not primed at the time the furnace is powered up, the furnace will run and

eventually produce enough condensate to cause the furnace to shut off. At that time the condensate

will flow out of the heat exchanger into the trap and the furnace will restart, resuming normal

operation.

NOTICE:

In all configurations, condensate drain tubing must be installed with continuous slope

down to the trap. Failure to do so will cause water to back into the furnace and prevent proper

operation. Damage to furnace and the creation of hazardous exhaust may occur.

CAUTION: Do not bypass pressure switches. They are critical safety features. If a pressure

switch functions, check for blockage. Do not circumvent pressure switches.

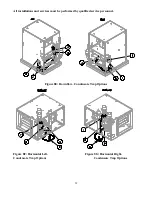

7. Plan, source, and install a condensate drain line using ½ inch diameter CPVC (chlorinated polyvinyl

chloride) thermoplastic pipe and pipefittings. In the event ½ inch PVC is preferred, a CPVC to PVC

adapter is included in the parts kit provided with the furnace. Route the line in the shortest possible

manner to reach a nearby drain. Secure all joints using cement. For gravity drainage, the condensate

drain line must maintain a minimum ¼ inch per foot downward slope toward the drain. The drain line

must be watertight, supported, and secured such that it cannot be easily moved.

NOTICE:

If an air conditioning condensate drain line is combined with the furnace condensate

drain line, the air conditioning evaporator coil must have a separate trap installed ahead of the

connection joint.

8. A condensate pump may be required when,

a suitable drain is not present,

the drain is above the trap outlet level on the furnace, or

the drain line cannot be sloped downward its full length to the drain.

9. CAUTION:

Continual exposure to condensate may injure plants and damage certain building

materials, including many metals, wood, stone, and concrete.

Summary of Contents for CLQS1-050T36N

Page 2: ......

Page 4: ......

Page 47: ...All installations and services must be performed by qualified service personnel 45...

Page 55: ...All installations and services must be performed by qualified service personnel 53...

Page 56: ...All installations and services must be performed by qualified service personnel 54...

Page 57: ...All installations and services must be performed by qualified service personnel 55...

Page 59: ...All installations and services must be performed by qualified service personnel 57...

Page 60: ...All installations and services must be performed by qualified service personnel 58...