Inspection and Reconditioning (Rev 1/97)

47

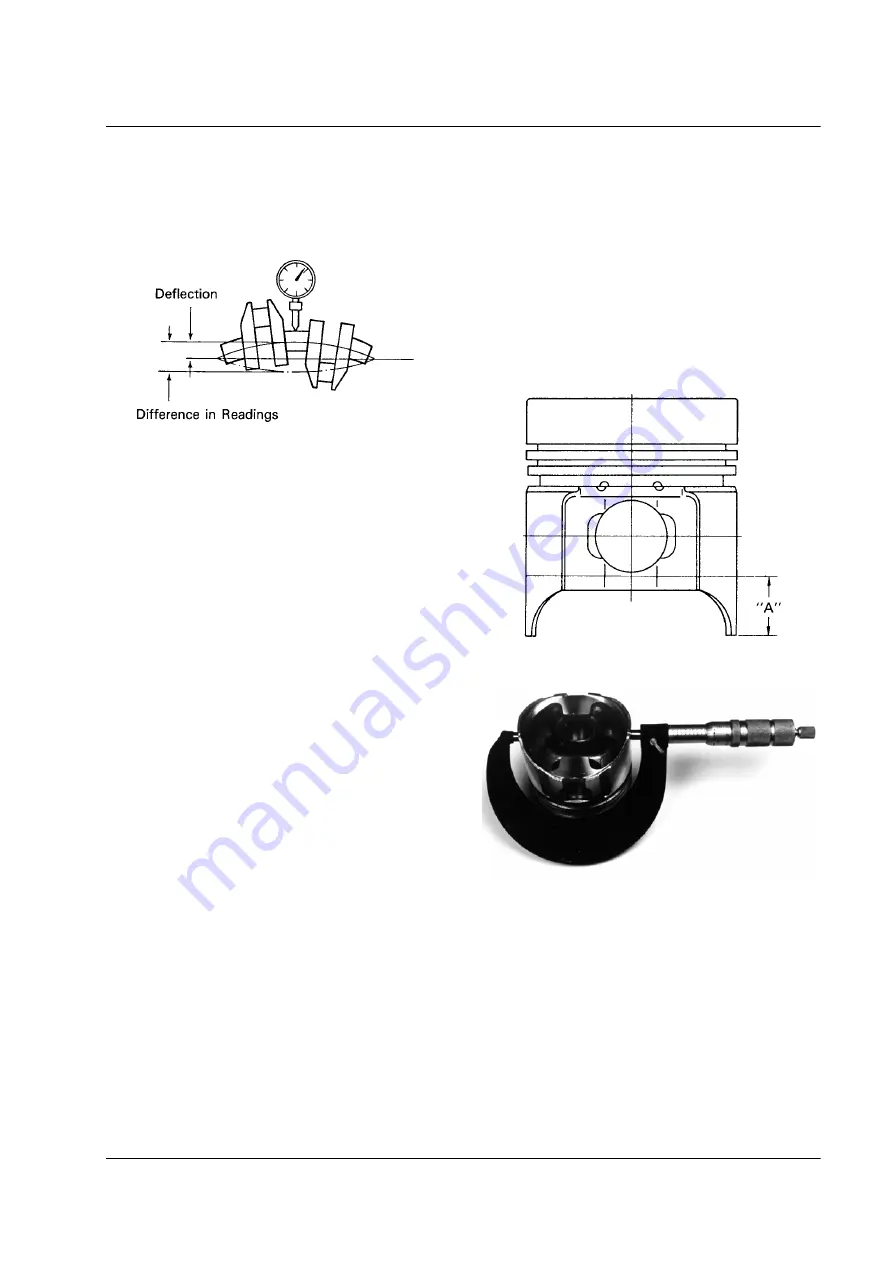

Crankshaft Deflection

5. Inspect the crankshaft timing gear for chipped or worn

teeth and for any cracks on or between the teeth. To

remove the gear use a standard gear puller. Install the

gear by pressing it onto the crankshaft. Apply a sealant

to the inside of the gear and to the outside of the crank-

shaft when installing the gear to prevent oil leaks.

Pistons

1. Remove and discard the old piston rings.

2. Remove the wrist pin circlips and push the wrist pin out

of the piston. If it is difficult to push the wrist pin out of

the piston, heat the piston in hot water that is at 120 to

140 F (49 to 60 C).

NOTE: Do not clamp a connecting rod in a vise with

steel jaws. Instead, use a vise that has soft jaws, or use

soft jaw covers. Clamping a connecting rod in the

steel jaws of a vise will put small nicks in the connect-

ing rod. These nicks raise the stress on the connecting

rod and can cause the connecting rod to break while

the engine is running.

3. Remove the carbon from the top of the piston but do

not scratch the piston. Clean the piston and inspect it

for damage. Replace the piston if it has any cracks, or if

the top of the piston is significantly burned or damaged.

aea243

4. Measure the outside diameter of each piston. This mea-

surement should be taken perpendicular to the wrist pin

at a specific distance, called “A”, above the bottom of

the piston skirt. Refer to Specifications for the sug-

gested values for distance “A”. If the piston is smaller

than the wear limit (refer to Specifications), replace the

piston.

Distance “A”

Measuring Piston

5. Clean the ring groves with a ring groove cleaner. Be

careful to avoid scraping any metal off the piston. If a

ring groove cleaner is not available, break a used ring

and sharpen the end. This can be used to clean the ring

grooves.

aea244

aea245