Fuel System (Rev 1/97)

98

CAUTION: Keep your hands away from the nozzle spray.

The nozzle spray is at such high pressure that it can break

the skin and penetrate into the underlying tissue. Such an

injury is very painful and can lead to serious complica-

tions such as blood poisoning.

Testing Injection Nozzles

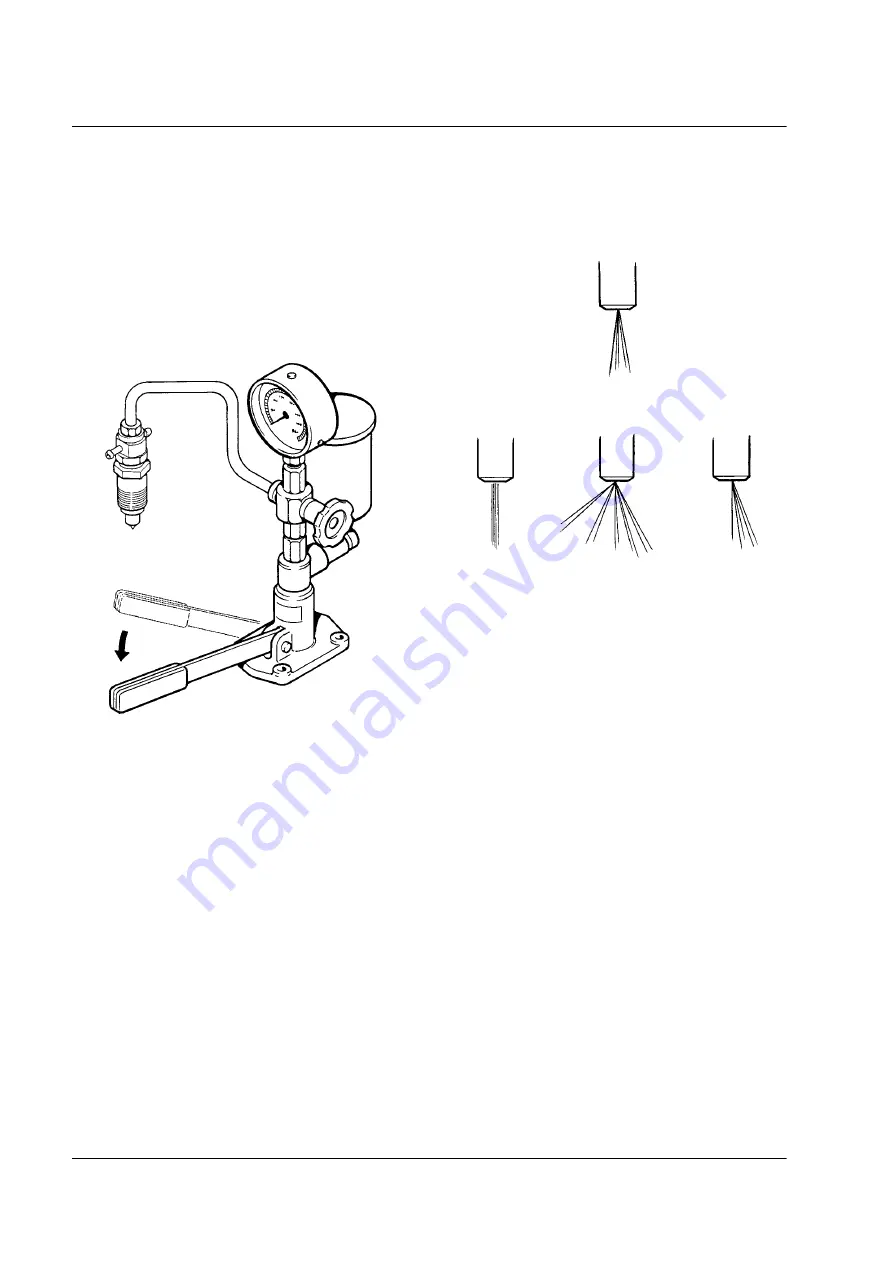

2. Close the pressure gauge valve and push the hand lever

completely down several times.

a.

The injection nozzle should make a shrill whistling

noise.

b. A straight conical spray pattern should form along

the center line of the injection nozzle, with a cone

angle of 5 to 10 degrees.

c.

The spray pattern should make a perfect circle on a

piece of paper placed 12 in. (300 mm) below the

injection nozzle.

aea358

Acceptable Spray Pattern

Unacceptable Spray Patterns

3. Open the pressure gauge valve and check the opening

pressure by pushing the hand lever completely down

several times.

a.

The injection nozzle should make a buzzing sound.

b. The opening pressure should be 1707 ± 73 psi

(11768 ± 500 kPa).

c.

Adjust the opening pressure by changing the num-

ber of adjustment shims above the spring. Refer to

the injection nozzle repair section.

4. Leave the pressure gauge valve open and check to see if

the injection nozzle drips by slowly pressing on the

hand lever to bring the pressure up to 300 psi (2068

kPa) below the opening pressure of the injection

nozzle. Maintain this pressure for at least 5 seconds.

Fuel should not drip from injection nozzle in less than 5

seconds.

5. Repair the injection nozzle if it fails any of these tests

or if fuel leaks out of the return collar ports during the

tests.

aea359

aea360