Fuel System (Rev 1/97)

99

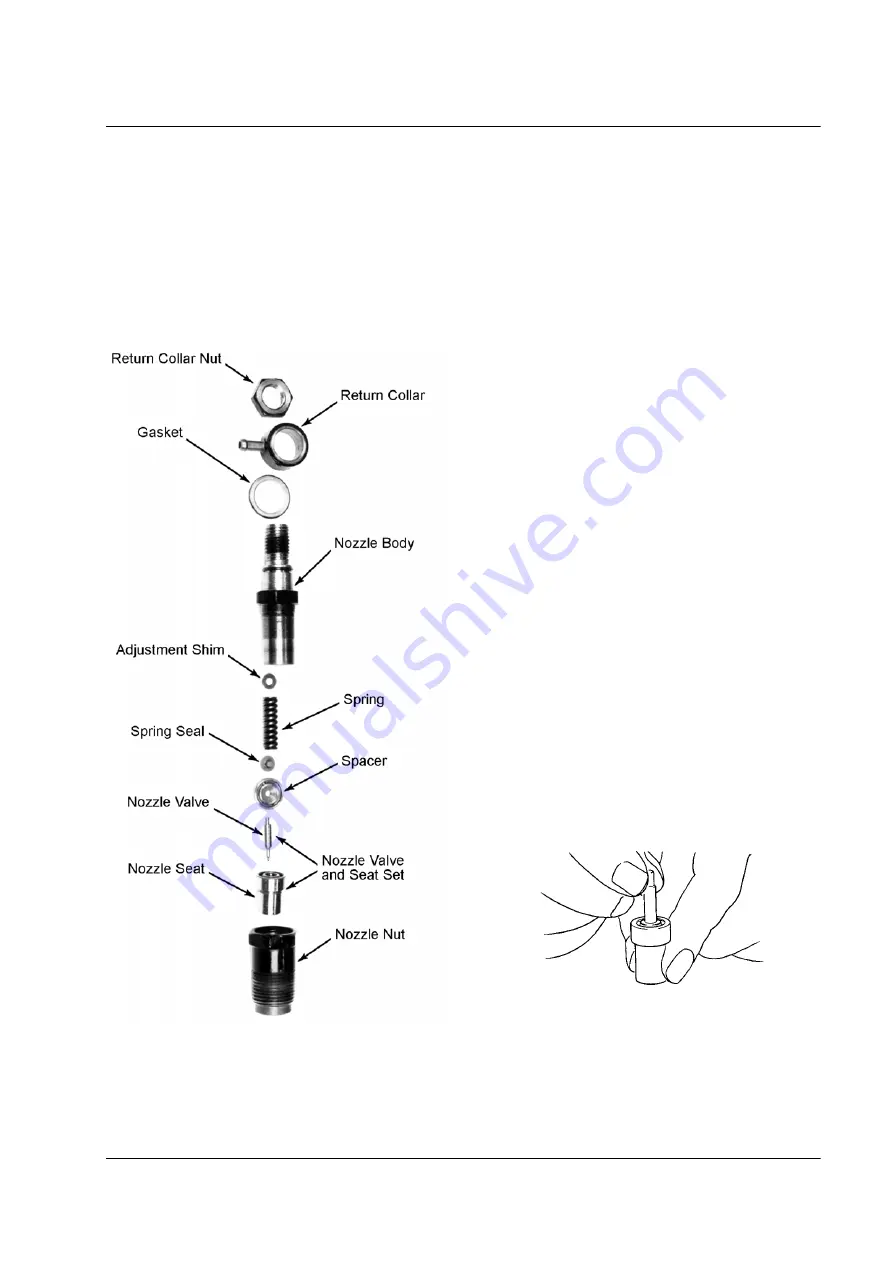

Repair

1. Place the nozzle body in a vise that has aluminum jaws

or jaw covers.

2. Loosen and remove the nozzle nut.

Injection Nozzle Assembly

aea361

3. Remove the nozzle valve and seat set from the nozzle

nut and submerge them in diesel fuel. Make sure to

keep them together as a set.

4. Remove the nozzle body from the vise.

5. Remove the spacer, spring seat, spring, and adjustment

shim from the nozzle holder.

6. Inspect the spacer. Replace the spacer if any wear or

damage is evident.

7. Inspect the spring. Replace the spring if it is bent,

scratched, or rusted.

8. Use a nozzle cleaning tool kit to clean the nozzle valve

and seat set.

a. Clean the carbon off the outside of the nozzle seat

with a brass brush.

b. Clean the inside of the nozzle with the cleaning

tools and solvent.

c. Thoroughly rinse the nozzle seat and valve with

cleaning spray and submerge them separately in

diesel fuel.

9. Test the nozzle valve and seat set.

a. Place the nozzle valve in the nozzle seat while

holding the nozzle seat in a vertical position.

b. Pull the nozzle valve about half way out of the

nozzle seat.

Testing Nozzle Valve and Seat Set

aea362