Inspection and Reconditioning (Rev 1/97)

44

d. Bore and hone each cylinder sleeve to obtain the

correct piston clearance.

4. Measure each piston. Bore and hone each cylinder to

obtain the correct piston to cylinder clearance (refer to

Specifications).

CAUTION: The pistons will vary slightly in diameter.

Therefore, each piston must be measured and each

cylinder must be bored and honed to match each pis-

ton.

The roughness average of the final surface finish in the

cylinders should be 59 to 118 micro inches (1.5 to 3.0

microns).

5. Measure the front camshaft bearing insert. If the front

camshaft bearing insert is larger than the wear limit

(refer to Specifications) or has a damaged surface,

remove the bearing insert with a bearing driver. If the

block will be boiled out, remove the bearing insert and

all the core plugs.

NOTE: The middle and rear camshaft bearings do not

have bearing inserts.

Measuring Front Camshaft Bearing Insert

aea297

6. Measure the middle and rear camshaft bearings. If the

middle or rear camshaft bearings are larger than the

wear limits (refer to Specifications), or if the surfaces

have been damaged significantly, replace the block.

Minor damage to the camshaft bearings can be cleaned

up with a brake cylinder hone. The camshaft bearings

should also be lightly honed after the block has been

boiled out.

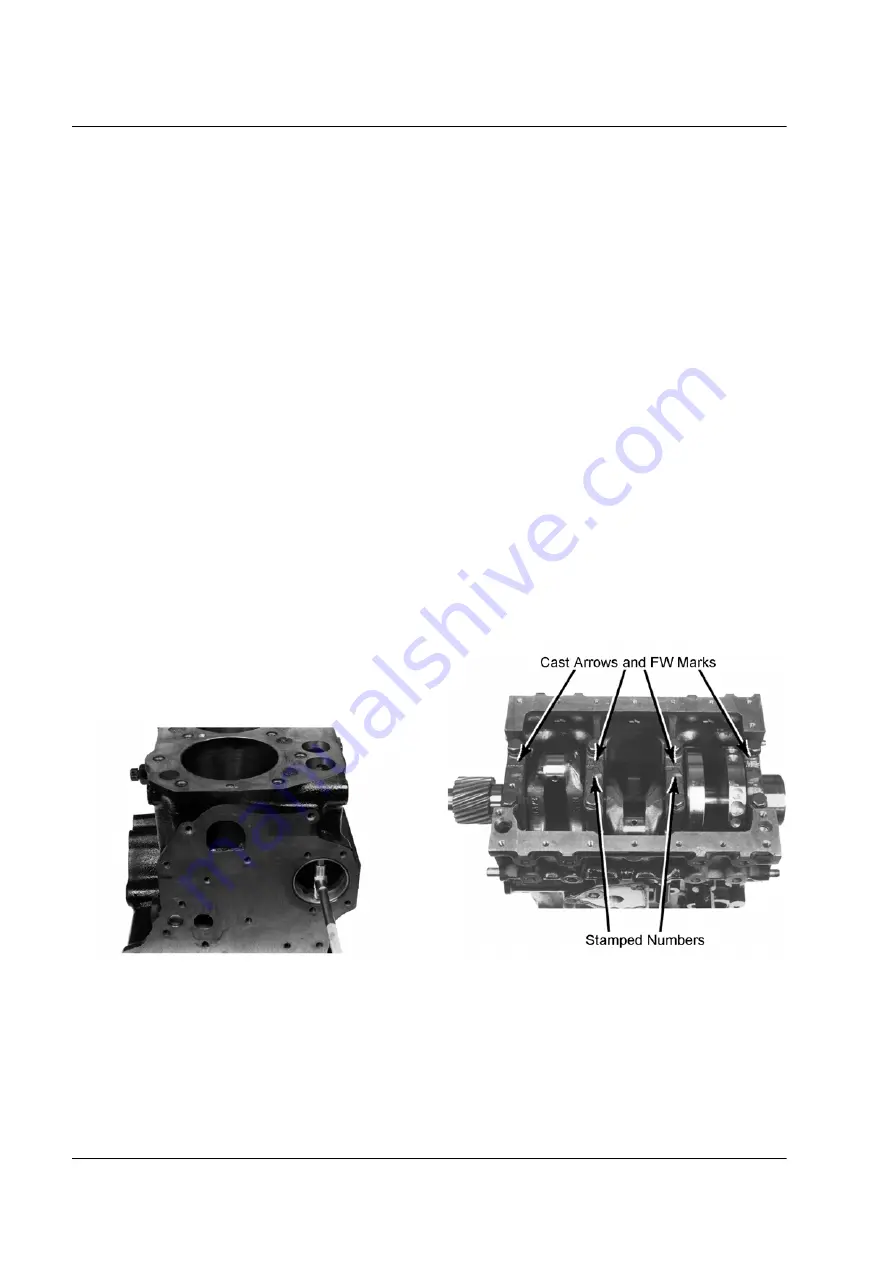

7. Install the main bearing caps in their proper positions.

The cast arrows are labeled FW and should point to the

rear (flywheel end) of the engine. The main bearing cap

that is machined for the thrust bearing goes to the rear

end of the engine. The main bearing caps with numbers

stamped on them go to the middle of the engine with

the main bearing cap marked number one closest to the

rear of the engine. The main bearing cap with no num-

ber goes to the front end of the engine. Torque the main

bearing cap bolts (refer to Specifications).

Main Bearing Cap Marks

aea236