PROVIDENCE INSERT

PELLET STOVE

10

INSTALLATION

The Providence Insert may be installed into a

Factory Built (Metal) fireplace, Masonry chimney,

or as a Built-in fireplace during new construction.

Each installation has its own clearance and

installation criteria as outlined in this manual.

Follow directions carefully as each of the three

installations vary and can be done in several ways. .

Factory Built (Metal) Fireplace Installation

A. Prior to planning placement of the Providence

Insert, the chimney MUST be swept of creosote

and soot. It should be inspected by a qualified

service professional.

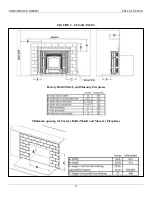

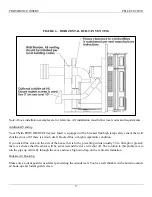

B. Mantle clearance to top of insert

– 12” (see

Figure 2).

C. Make sure the Providence Insert will fit into

your existing fireplace by measuring dimension

according to Figures 1 & 2. See Figure 8 for

adjustable Hopper Assembly.

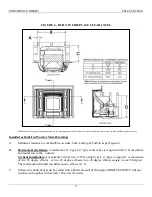

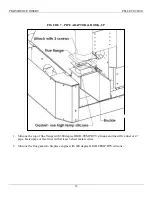

D. Exhaust vent pipe and outside combustion air

intake (if used) can be configured as shown in

figures 3A-3D.

The Providence Insert uses 4”

type L pipe with a m

aximum height of 25’.

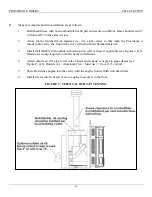

E. Pellet vent connections must be sealed with a

liberal amount of 500 degree HIGH-TEMP

RTV silicone and screwed together with at least

3 sheet metal screws.

F. Pellet vent (exhaust vent) termination must be

sealed on top of chimney to prevent water from

entering fireplace cavity.

G. It is recommended that a metal plate be installed

to seal the damper area with clearance hole to

allow exhaust vent pipe to pass through. Use

non-flammable insulation to seal edges and to

prevent heat loss.

H. Aluminum flex pipe can be used to bring

outside air into the stove. Use a stainless hose

clamp to crimp flex to stove air intake flange.

Outside Air

–

Aluminum Flex

– Must use 3” if

over 10’ vertical.

I. When hooking up the outside air you must be

sure that a rodent guard is used on through wall

installs. Many pellet pipe manufacturers make

wall thimbles with the rodent guard built into

the thimble.

1.

The firebrick (refractory), glass

doors, screen rails, screen mesh, and

log grates can be removed from a

factory built firebox in order to gain

minimum fireplace insert opening

requirements.

2.

Smoke shelves, shields and baffles

may be removed from a factory-built

fireplace if attached with mechanical

fasteners.

3.

Items can only be removed if they

are mechanically fastened to the

Factory Built (Metal) fireplace. No

cutting or other permanent removal

of components is allowed. All

removed components must be saved

so that the Factory Built (Metal)

fireplace can be returned to a

burnable state.

4.

Floor Protection: Hearth extension

from door opening required is

6”

.

Floor protection to the side of the

door opening is also

6”.

5.

The enclosed label stating “THIS

FIREPLACE

HAS

BEEN

ALTERED TO ACCOMMODATE

A FIREPLACE INSERT AND

SHOULD BE INSPECTED BY A

QUALIFIED PERSON PRIOR TO

REUSE AS A CONVENTIONAL

FIREPLACE. “

must be attached to

the fireplace with screws or nails.

Summary of Contents for providence

Page 6: ...PROVIDENCE INSERT PELLET STOVE 6 LABORATORY LISTING LABEL...

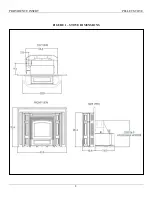

Page 8: ...PROVIDENCE INSERT PELLET STOVE 8 FIGURE 1 STOVE DIMENSIONS...

Page 19: ...PROVIDENCE INSERT PELLET STOVE 19 FIGURE 8 ADJUSTABLE HOPPER ASSEMBLY...

Page 20: ...PROVIDENCE INSERT PELLET STOVE 20 FIGURE 9 CONTROL PANEL...

Page 31: ...PROVIDENCE INSERT PELLET STOVE 31 FIGURE 13 CLEAN OUT COVERS FIGURE 14 CLEAN OUT VENT PORT...

Page 32: ...PROVIDENCE INSERT PELLET STOVE 32 FIGURE 15 COMBUSTION FAN...

Page 37: ...PROVIDENCE INSERT PELLET STOVE 37 FIGURE 18 ELECTRICAL SCHEMATIC WIRING DIAGRAM...

Page 40: ...PROVIDENCE INSERT PELLET STOVE THELIN HEARTH PRODUCTS 63 Laxalt Dr Carson City NV 89706...

Page 41: ......