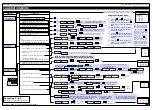

Tiger 320 Series Programming Code Sheet

Draft Copy. Code Version V3.08a

Texmate Inc. Tel. (760) 598 9899 • www.texmate.com

4

2 February, 2005 Prog. Code Sheet V3.08a (NZ101)

Tiger 320 Series Code Logic Diagram

To enter press the

and

buttons at the same time

P

Calibration Modes for Input and Output

Code 1 – Display Configuration

Code 2 – CH1 Measurement Task & Sampling Rate

Code 3 – CH1 Post Processing & Serial Mode Functions

Code 4 – CH2 Measurement Task & 32-point Linearization

Code 5 – CH3 Functions

Code 6 – CH4 Functions

Code 7 – Result Processing

Code 8 – Data Logging & Print Mode

Code 9 – Functions for Digital Input Pins

[CAL]

[Cod_1]

[Cod_2]

[Cod_3]

[Cod_4]

[Cod_5]

[

Cod_6]

[Cod_7]

[Cod_8]

[Cod_9]

To enter press the

and

buttons at the same time

P

Setpoint 1

[SP_1]

Setpoint Activation Values Mode

Setpoint 2

[SP_2]

Setpoint 3

[SP_3]

Setpoint 4

[SP_4]

Setpoint 5

[SP_5]

Setpoint 6

[SP_6]

Enter these menus to set setpoint

(SP) activation values

Setpoint 1

[SPC_1]

Setpoint & Relay Control Settings Mode

Setpoint 2

[SPC_2]

Setpoint 3

[SPC_3]

Setpoint 4

[SPC_4]

Setpoint 5

[SPC_5]

Setpoint 6

[SPC_6]

Enter these menus to configure SP control

settings

See Page 5 for code settings to calibrate the meter’s input and output signals.

See Page 6 for code settings to configure the setpoint annunciators and other

display functions.

See Page 7 for code settings to configure the CH1 measurement task and sam-

pling rate.

See Page 8 for code settings to configure CH1 post processing and serial

mode functions.

See Page 8 for code settings to configure the second channel (CH2) meas-

urement task and 32-point linearization settings when using dual input signal

conditioners.

See Page 8 for code settings to configure the third channel (CH3) when using

triple input signal conditioners.

See Page 9 for code settings to configure the fourth channel (CH4) when

using quad input signal conditioners.

See Page 9 for code settings to configure the meter for processing the result

of CH1 and CH2.

See Page 9 for code settings to configure data logging and data printing

using the meter.

See Page 9 for code settings to configure the meter for inputs from external

sources through the digital input pins.

The

Setpoint and

Relay Control

Settings

diagram

on Pages 8, 9, and

10 shows the three

digit configuration

settings that are

applied individually

to each setpoint.

Display Brightness

[bri]

Allows you to adjust the display brightness in a range of 8 settings. 0 being

dull, 7 being bright.

Code 10 – Bargraph Setup

[Cod10]

See Page 10 for code settings to configure the meter’s bargraph display.

Main Programming Mode

Setpoint Programming Mode

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

Operational Display

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

Operational Display

P

Default setting = 18000

Default setting = –18000

Default setting = 5000

Default setting = –5000

Default setting = 10000

Default setting = –10000

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

Operational Display

Tiger 320 Series Programmable Meter Controllers (PMCs) come in

two versions: the economy E version, or the top-of-the-line T version.

The standard E version comes with 4 kilobits of EEPROM installed,

whereas the standard T version comes with 32 kilobits of EEPROM

Installed. Also, the T version can have a macro installed.

The standard 4-kilobit E version can be upgraded to 32 or 512 kilobits.

The standard 32-kilobit T version can be upgraded to 512 kilobits. The

amount of EEPROM installed in the controller determines the range of

functions it is capable of performing. The following table lists the func-

tions that require specific amounts of memory.

Version

Functions

Memory

(kilobits)

Remarks

E

1 linearization table

4 (standard)

Table 1 is available to

be applied to chan-

nels 1 to 4 and result.

4 linearization tables

32

Tables 1 to 4 are

available to be

applied to channels 1

and 2 and result.

Table 3 can be applied

to channel 3.

Table 4 can be applied

to channel 4.

All four tables can be

cascaded to form a

single 125-point lin-

earization table avail-

able to be applied to

channels 1 and 2 and

result.

Data logging

512

With 512 kilobits

installed, the controller

can perform data log-

ging functions along

with complete lin-

earization functionali-

ty. With a real-time

clock installed, date

and time stamps can

be included.

T

4 linearization tables

32 (standard)

As for E version with

32 kilobits installed.

Macro programming

A macro can be pro-

grammed to suit a

user's logic control

application.

Data logging

512

As for E version with

512 kilobits installed,

but with macro pro-

gramming functionali-

ty available.

E/T Versions of Tiger 320 Series Programmable Meter Controller