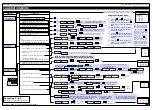

Tiger 320 Series Programming Code Sheet

Draft Copy. Code Version V3.08a

Texmate Inc. Tel. (760) 598 9899 • www.texmate.com

13

2 February, 2005 Prog. Code Sheet V3.08a (NZ101)

P

[diSP]

[rESLt]

[Ch1]

[Ch2]

[Ch3]

[Ch4]

[tot_1]

[tot_2]

[PEAK]

[VALEY]

[tArE]

[1 to 244]

P

P

P

Use the

buttons to cycle

through the menu

[brEAK]

[both]

[LEVEL]

Sets from 0 to –19999

[i-S+C]

[d+C]

[rEG]

Sets from 0 to 99999

Select Reset Destination Register

Select Reset Trigger

Select Reset Mode

Select Reset Constant

P

Select Print Triggered by Setpoint

P

Select Log Triggered by Setpoint

Advanced Functions Mode – Set Up Register Reset and Setpoint Trigger Functions

From Page 11,

3rd digit [XX7]

Selecting any destination

register takes you to

Mode Reset

Selecting [oFF] in the Destination

Register Reset Setup takes you

to Setpoint Print Trigger Setup

Select [rEG] to access the source parameter

to select the number of the Modbus register in

the meter to be copied to the reset destination

register

X

X

P

X

X

Reset SPC to XX0

X

X

Use the

buttons to cycle

through the menu

Programming Tip

If you do not require any

of the functions in this

mode, ensure it is set to:

Use the

buttons

to select a register as the

data source for the set-

point (1 to 244)

Programming Tip

This mode can not be accessed if

SPC_1 or SPC_2 is in the PID mode.

Select reset

trigger from

1 of 4 relay

operating

edges

Reset Trigger

Select register to be reset

Reset Destination Register

Select [Reg] in

reset mode

Reset Mode

Copy contents

of selected

register

SP1

to

SP6

Contents of

register copied into

reset destination

register

Reset Destination Mode

The reset destination mode allows you to select a reg-

ister to be reset using the contents of another register

triggered by a setpoint. See diagram below.

Reset Trigger

Select the reset trigger from 1 of 4 relay operating

modes.

Reset Destination Register

Select the register to be reset from the commonly

used register set 1 to 244.

Reset Mode

1.

Select [rEG].

2.

Contents of selected register copied into reset

destination register.

[TOT_1]

[TOT_2]

[TARE]

[RESULT]

[CH1]

[CH2]

[CH3]

[CH4]

[DISP]

[ 1]

[ 2]

.....[ 10]

[ 11]

[ 12]

.....[ 20]

[ 100]

[ 200]

.....[ 239]

The

button takes you forward,

the

button takes you back.

[AUX_5]

[VALLEY]

[PEAK]

[AUX_4]

[AUX_3]

[AUX_2]

[AUX_1]

Constant pressure on the

button moves thru

Registers 1 to 239 one register at a time until

you get to ten, then it jumps in multiples of 10,

until you reach 100, then it jumps in multiples of

100.

Stopping and starting again resumes single

steps forward.

Use the

and

buttons to cycle through

the Registers Menu and

Registers (1 to 239) to

select the data source

for displays, peak and

valley, totalizers and

analog output.