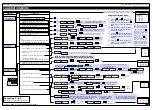

Tiger 320 Series Programming Code Sheet

Draft Copy. Code Version V3.08a

Texmate Inc. Tel. (760) 598 9899 • www.texmate.com

2

2 February, 2005 Prog. Code Sheet V3.08a (NZ101)

SP1

SP2

SP3

SP4

SP5

SP6

Prog.

SP1

SP2

SP3

SP4

SP5

SP6

Prog.

SP1

SP2

SP3

SP4

SP5

SP6

Prog.

SP1

SP2

SP3

SP4

SP5

SP6

Prog.

SP1

SP2

SP3

SP4

SP5

SP6

Prog.

MODEL &

SOFTWARE

CODE VERSION

CHECK

Press

then

once

release

Press

and

hold

Step 1

Step 2

Step 3

The above displays toggles

three times before returning to

the operational display

SP1

SP2

SP3

SP4

SP5

SP6

Prog.

Operational Display

Operational Display

Example

Release

after

pressing

Prog.

Model

Number

Typical

Software

Version

Number

Press and hold

the and

buttons

While holding both

buttons, press the Prog.

button then release

all three buttons

Programming Tip

The

Model and Software Code Version

check-

ing procedure can be performed at any time

without interfering with other configuration

settings.

ST

ST

AR

AR

T HERE

T HERE

a

b

c

Model No:

............................................................................

Software Version No:

..................................................

Customer ID:

......................................................................

Macro ID:

..............................................................................

Initial Setup Procedures

Model and Software Code Version Check

The meter model and software code version number can be

checked at any time while in the operational display using the

following procedure.

Before configuring the meter, carry out the following meter

configuration checks:

• Model and software code version check.

• Code blanking and macro check.

After powering-up the meter, check the model and software

code version number and note this below.