December 2019

Service and Repair Manual

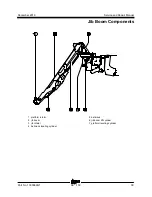

Boom Components

Part No. 1300669GT

SX

™

-150

53

28 Remove the fasteners securing the lower wear

pads and remove the wear pads and

aluminum block between the #1 and #2 boom

tubes.

29 Back the wire cables from the opening below

the #1 boom tube into the tube and then push

them out the end of the #1 boom tube.

Note: This will allow the retract cables to come out

with the boom tubes. Remove the retract wire

cables with the #2 boom tube

30 Begin pulling the #2 boom tube from the

#1 boom tube.

Note: Make sure the tube remains parallel to the

#1 boom tube while removing.

31 When approximately 10 feet of the #2 boom

tube remains in the #1 boom tube, attach a

strap from a suitable overhead lifting device

and slightly lift the tube.

Crushing hazard. The number

2 boom tube may become

unbalanced and fall when it is

removed from the number

1 boom tube if it is not properly

supported and attached to the

overhead crane.

Note: During removal, the overhead crane strap will

need to be adjusted for proper balancing.

32 Remove the final two side wear pads from the

platform end of the machine.

Note: Pay careful attention to the location and

amount of shims used with each wear pad.

33 Support and slide the #2 boom tube from the

boom assembly.

4-3

Primary Boom Lift Cylinder

The primary boom lift cylinder raises and lowers

the primary boom. The primary boom lift cylinder is

equipped with a counterbalance valve to prevent

movement in the event of a hydraulic line failure.

How to Remove the Boom Lift

Cylinder

Bodily injury hazard. This

procedure requires specific repair

skills, lifting equipment and a

suitable workshop. Attempting

this procedure without these skills

and tools could result in death or

serious injury and significant

component damage. Dealer

service is strongly recommended.

Note: When removing a hose assembly or fitting,

the O-ring (if equipped) on the fitting and/or hose

end must be replaced. All connections must be

torqued to specification during installation. Refer to

Specifications,

Hydraulic Hose and Fitting Torque

Specifications.

1 Raise the boom until there is approximately

4 feet / 1.2 m between the turntable and boom

rest pad.

2 Attach a lifting strap from an overhead crane

or other suitable lifting device to the rod end of

the the boom lift cylinder.

Summary of Contents for Genie SX-150

Page 105: ...December 2019 Service and Repair Manual Manifolds Part No 1300669GT SX 150 93 ...

Page 107: ...December 2019 Service and Repair Manual Manifolds Part No 1300669GT SX 150 95 ...

Page 109: ...December 2019 Service and Repair Manual Manifolds Part No 1300669GT SX 150 97 ...

Page 117: ...December 2019 Service and Repair Manual Part No 1300669GT SX 150 105 ...

Page 119: ...December 2019 Service and Repair Manual Part No 1300669GT SX 150 107 ...

Page 122: ...Service and Repair Manual December 2019 Manifolds 110 SX 150 Part No 1300669GT ...

Page 124: ...Service and Repair Manual December 2019 Manifolds 112 SX 150 Part No 1300669GT ...

Page 229: ...December 2019 Service and Repair Manual 217 Control Circuits Horn ...

Page 230: ...Service and Repair Manual December 2019 218 SX 150 Part No 1300669GT Control Circuits Horn ...

Page 231: ...December 2019 Service and Repair Manual Part No 1300669GT SX 150 219 Control Circuits Power ...

Page 232: ...Service and Repair Manual December 2019 220 Control Circuits Power ...

Page 233: ...December 2019 Service and Repair Manual 221 Control Circuits Can Bus ...

Page 234: ...Service and Repair Manual December 2019 222 SX 150 Part No 1300669GT Control Circuits Can Bus ...

Page 236: ...Service and Repair Manual December 2019 224 Control Circuits Deutz TD2011L04i Engine ...

Page 237: ...December 2019 Service and Repair Manual 225 Control Circuits Deutz TD 2 9 L4Engine ...

Page 240: ...Service and Repair Manual December 2019 228 Control Circuits Perkins 1104D 44T Engine ...

Page 241: ...December 2019 Service and Repair Manual 229 Control Circuits Perkins 854F 34T Engine ...

Page 244: ...Service and Repair Manual December 2019 232 Control Circuits Axle Extend Retract ...

Page 245: ...December 2019 Service and Repair Manual 233 Control Circuits Steering ...

Page 247: ...December 2019 Service and Repair Manual Part No 1300669GT SX 150 235 Control Circuits Propel ...

Page 248: ...Service and Repair Manual December 2019 236 Control Circuits Propel ...

Page 249: ...December 2019 Service and Repair Manual 237 Control Circuits Turntable Rotate ...

Page 252: ...Service and Repair Manual December 2019 240 Control Circuits Boom Up Down ...

Page 253: ...December 2019 Service and Repair Manual 241 Control Circuits Boom Extend Retract ...

Page 261: ...December 2019 Service and Repair Manual 249 Control Circuits Recovery PLD ...

Page 264: ...Service and Repair Manual December 2019 252 Control Circuits Telematics ...

Page 265: ...December 2019 Service and Repair Manual 253 Generator Receptacle Wiring ANSI CSA ...

Page 268: ...Service and Repair Manual December 2019 256 Generator Receptacle Wiring CE ...

Page 269: ...December 2019 Service and Repair Manual 257 Perkins 1104D 44T Engine Electrical Schematic ...

Page 272: ...Service and Repair Manual December 2019 260 Perkins 854F 34T Engine Electrical Schematic ...

Page 273: ...December 2019 Service and Repair Manual 261 Perkins 854F 34T Engine Harness ...

Page 276: ...Service and Repair Manual December 2019 264 Deutz TD 2 9 L4 Engine Electrical Schematic ...

Page 277: ...December 2019 Service and Repair Manual 265 Deutz TD 2 9 L4 Engine Harness ...

Page 279: ...December 2019 Service and Repair Manual 267 Hydraulic Schematic ...

Page 280: ...Service and Repair Manual December 2019 268 Hydraulic Schematic ...

Page 282: ......