Service and Repair Manual

June 2021

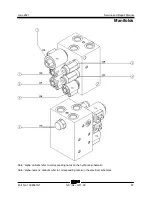

Steer Axle Components

100

GS

™

-84 • GS

™

-90

Part No. 1306587GT

9-1

Yoke and Drive Motor

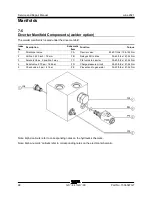

How to Remove the Yoke and Drive Motor

How to Remove the Yoke and

Drive Motor

Note: When removing a hose assembly or fitting,

the O-ring (if equipped) on the fitting and/or hose

end must be replaced. All connections must be

torqued to specification during installation. Refer to

Specifications,

Hydraulic Hose and Fitting Torque

Specifications.

Note: When installing a steer yoke, Loctite® 243™

threadlocker must be applied to the retaining

fasteners securing the king pins. Torque to 44 ft-

lbs / 60 Nm.

1 Chock both sides of the wheels at the non-

steer end of the machine.

2 Center a lifting jack under the drive chassis at

the steer end of the machine.

3 Loosen the wheel lug nuts. Do not remove

them.

4 Raise the machine approximately 2 inches /

5 cm. Place blocks under the chassis for

support.

Crushing hazard. The chassis

will fall if not properly supported.

5 Remove the wheel lug bolts. Remove the tire

and wheel assembly.

6 Remove the hose clamps retaining fasteners

from the drive motor guard. Remove the hose

clamps.

7 Remove the retaining fasteners from the drive

motor guard. Remove the drive motor guard

from the yoke.

8 Tag, disconnect and plug the hoses from the

drive motor. Cap the fittings on the drive

motor.

Bodily injury hazard. Spraying

hydraulic oil can penetrate and

burn skin. Loosen hydraulic

connections very slowly to allow

the oil pressure to dissipate

gradually. Do not allow oil to

squirt or spray.

9 Support and secure the yoke and drive motor

assembly to a lifting jack.

10 Remove the cotter pin from the tie rod clevis

pin.

Note: Always use a new cotter pin when installing

a clevis pin.

11 Remove the retaining fastener from the steer

cylinder rod end pivot pin. Remove the pivot

pin.

12 Remove the retaining fastener from the lower

yoke pivot pin.

13 Place a rod through the pin and twist to

remove the pin.

14 Repeat steps 11 and 12 for the upper yoke

pivot pin.

15 Remove the yoke and drive motor assembly

from the machine.

Crushing hazard. The yoke and

drive motor assembly may

become unbalanced and fall if

not properly supported and

secured to the lifting jack when it

is removed from the machine.

Summary of Contents for Genie GS-3384

Page 185: ...June 2021 Service and Repair Manual 171 Ford MSG 425 Engine Wire Harness...

Page 188: ...Service and Repair Manual June 2021 174 Deutz D 2 9 L4 Engine Wire Harness...

Page 189: ...June 2021 Service and Repair Manual 175 Deutz TD 2 2 L3 Engine Wire Harness...

Page 192: ...Service and Repair Manual June 2021 178 Deutz TD 2 2 L3 Engine Wire Harness...

Page 193: ...June 2021 Service and Repair Manual 179 Hydraulic Schematic...

Page 194: ...Service and Repair Manual June 2021 180 GS 84 GS 90 Part No 1306587GT Hydraulic Schematic...

Page 195: ...June 2021 Service and Repair Manual Part No 1306587GT GS 84 GS 90 181 Hydraulic Schematic...

Page 196: ...Service and Repair Manual June 2021 182 Hydraulic Schematic...

Page 197: ...June 2021 Service and Repair Manual 183 Electrical Schematic Ford Engine Models ANSI CSA...

Page 200: ...Service and Repair Manual June 2021 186 Electrical Schematic Ford Engine Models ANSI CSA...

Page 201: ...June 2021 Service and Repair Manual 187 Electrical Schematic Deutz Engine Models ANSI CSA...

Page 204: ...Service and Repair Manual June 2021 190 Electrical Schematic Deutz Engine Models ANSI CSA...

Page 206: ...Service and Repair Manual June 2021 192 Electrical Schematic SCON ANSI CSA...

Page 207: ...June 2021 Service and Repair Manual 193 Electrical Schematic Ford Engine Models AS CE...

Page 210: ...Service and Repair Manual June 2021 196 Electrical Schematic Ford Engine Models AS CE...

Page 211: ...June 2021 Service and Repair Manual 197 Electrical Schematic Deutz Engine Models AS CE...

Page 214: ...Service and Repair Manual June 2021 200 Electrical Schematic Deutz Engine Models AS CE...

Page 217: ......