MAINTENANCE

3Ć5

186E MM160 (6–94)

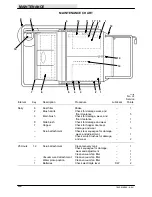

No. of

Service

Interval

Key

Description

Procedure

Lubricant

Points

50 Hours

14

Vacuum fan belt

Check tension and wear

–

1

10

Propelling belts

Check tension and wear

–

2

10

Main brush belts

Check for wear

–

2

9

Side brush belt

Check tension and wear

–

2

8

Side brush

Check floor pattern

–

1

3

Main brush

Check floor pattern

–

1

Rotate end-for-end

–

1

4

Brush arm pivot

Lubricate

SPL

2

13

Rear caster

Lubricate

SPL

2

12

Scrub attachment

Lubricate squeegee pivot

SPL

1

Check debris tray floor clearance

–

1

–

Check scrub brush pattern

–

2

7

Hopper

Check floor clearance

–

1

100 Hours

5

Drive chains

Check and adjust tension

–

2

Lubricate

SO

2

7

Hopper

Clean inside

–

1

Check floor clearance

–

1

6

Dust filter

Clean or replace

–

1

11

Self adjusting sheave

Lubricate

EO

1

1

Batteries

Clean top surface and terminals

DW

2

17

Differential

Lubricate

SPL

1

400 Hours

15

Propelling motor

Blow out dust and inspect

–

1

16

Side brush gear box

Check lubricant level

GL

1

EO – Engine oil

DW – Distilled water

SPL – Special lubricant, Lubriplate EMB grease, TENNANT Part No. 01433–1

SO – Spray lubricant

GL – SAE 90 Weight gear lubricant

NOTE: More frequent intervals may be required in extremely dusty conditions.