Falcon GC

Maintenance & Troubleshooting

Teledyne Analytical Instruments

27

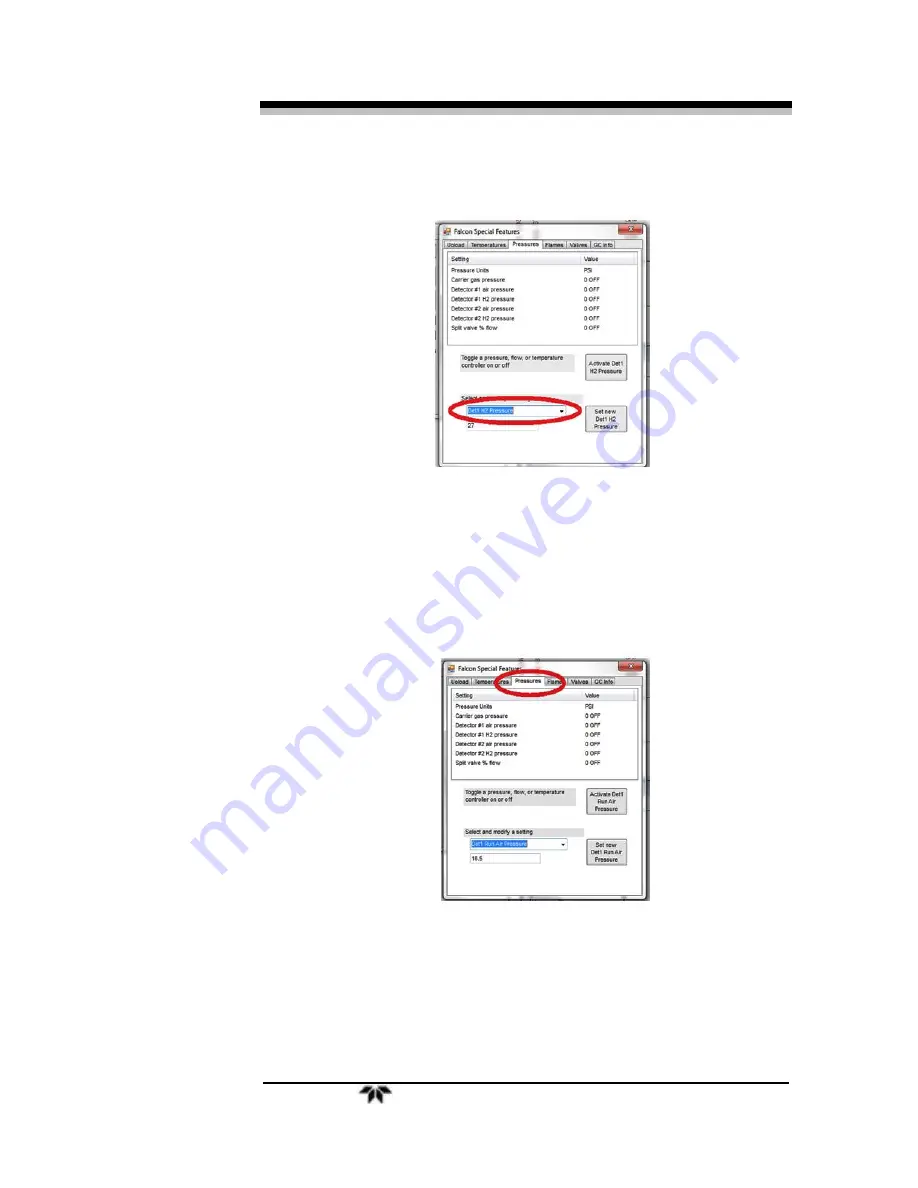

Select “Det1 Ign Air Pressure” from the dropdown menu.

6.

Adjust the flow until it is at 65mL/min.

i.

With the FID H

2

flow off adjust the IGN Air pressure until a

flow of 65mL/min is obtained.

ii.

Record this value

7.

Select “Det1 Run Air Pressure” from the dropdown menu.

8.

Adjust the flow until it is at 150mL/min.

i.

With the FID H2 flow off adjust the pressure until a flow

of 150mL/min is reached.

ii.

Record this value.

Summary of Contents for FALCON GC

Page 10: ...Falcon GC x Teledyne Analytical Instruments Blank Page ...

Page 15: ...Falcon GC Preparatio n Teledyne Analytical Instruments 5 3 Click on Report ...

Page 16: ...Preparation Falcon GC 6 Teledyne Analytical Instruments Blank Page ...

Page 42: ...Maintenance Troubleshooting Falcon GC 32 Teledyne Analytical Instruments ...

Page 62: ...Appendix Falcon GC 52 Teledyne Analytical Instruments A 3 Drawings ...

Page 63: ...Falcon GC Appendix Teledyne Analytical Instruments 53 ...

Page 64: ...Appendix Falcon GC 54 Teledyne Analytical Instruments ...

Page 65: ...Falcon GC Appendix Teledyne Analytical Instruments 55 ...

Page 66: ...Appendix Falcon GC 56 Teledyne Analytical Instruments ...

Page 67: ...Falcon GC Appendix Teledyne Analytical Instruments 57 ...