12

Test button

The control can be made to cycle through a test routine whenever the Test button is pushed. The

test can be halted at certain times by pushing the button a second time. For details of the test

routine, refer to the description starting on the next page.

Test

Boiler Differential and Time Delay

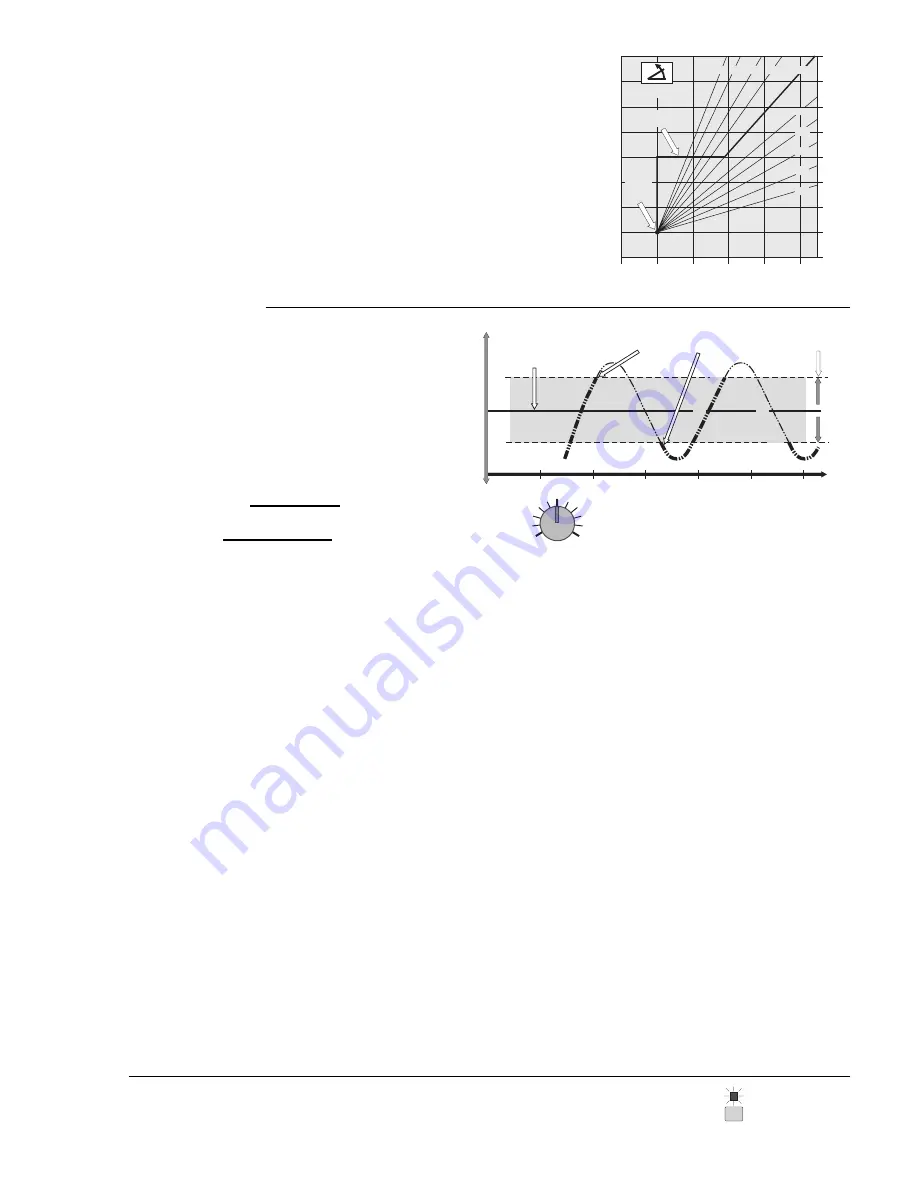

The Boiler Differential adjustment sets how much the actual

supply water temperature may deviate from the desired tempera-

ture before stages are turned on or off, and is determined by the

flow rate past the supply sensor relative to the amount of heat

produced by each stage. To prevent short operating cycles of the

boilers the control has a delay of at least 1 minute between firing

cycles. On an installation where flow rates are known, the Boiler

Differential can be calculated as follows:

Desired temperature

this example

160

°

F(71

°

C)

T

emperature

W

armer

Cooler

Time

Differential

this example

10

°

F(5

°

C)

165

°

F(74

°

C)

155

°

F(68

°

C)

Te

m

p

e

ra

tu

re

fa

ll

Staging

OFF ON

Te

m

p

e

ra

tu

re

r

is

e

Boiler Differential =

For example:

=

10

°

F (6

°

C)

Btu/hr

US GPM x 500

100,000 Btu/hr

20 US GPM x 500

Trial setting = 22

°

F if

flow rates are unknown

22

°

F

2

42

Boiler

Differential

All boilers will eventually turn on when the temperature falls

and stays 5

°

F (3

°

C) below the desired temperature. Delays of 1 to

5 minutes for staging on depend on the degree of control error (P+I+D). As the temperature rises to within the differential range,

no boilers are staged on or off. All boilers will eventually turn off when the temperature rises

and stays 5

°

F (3

°

C) above the desired

temperature. Delays of 8 seconds to 3 minutes for staging off depend on the degree of control error.

Setting a boiler differential for modular boilers is often complicated

by the fact that flow rates and heating loads may vary widely, and

at times boiler outputs may not be balanced to the load. Observing

the "Target Supply" fixed display while the boilers are staging can

assist the user in understanding system flow and boiler problems.

The ideal control reaction occurs when the target supply tempera-

ture remains constant or only changes slightly during the staging

process, indicating a well balanced and constant – or slowly

changing – load vs. output in the system.

If the target supply temperature decreases

rapidly when a boiler

comes on, it indicates a heavy derivative action by the control in

response to a rapid supply temperature increase. This type of

action typically indicates a condition where the boiler output is far

in excess of the load, a situation that is usually the result of a system

that is operating with only a few zones open (decreased load).

Setting a wider differential and ensuring a minimum fixed load (wild

loops) can help minimize this problem.

If the target supply temperature increases

rapidly, it indicates a

heavy derivative action by the control in response to a rapid load

increase. This type of action typically indicates situations where the

load is not finely divided (a few large zones) and is usually the result

of one large zone opening – or a system coming out of setback –

and delivering cold water to the boilers (increased load). Typically,

this will cause many or all of the boilers to be staged on with

minimum delay, which is the correct control action for the situation.

If the load fluctuates rapidly and repeatedly from heavy to light,

some instability may result in the staging process as the control

tries to bring on many boilers at once and then shut them off again

when the load suddenly decreases. The target temperature will be

constantly increasing and decreasing. Setting a wider differential

will help to stabilize the control action in many of these cases.

If the target supply temperature slowly and continually climbs, it

indicates that the supply temperature is not rising to the target

temperature. The control will continue to request more and more

boilers until the supply temperature rises sufficiently to reduce the

control error. This problem is called "Reset Windup" and can occur

in systems where: (a) the boilers are undersized, (b) flow is

interrupted –

without removing the heat demand – to the point

where the supply sensor cannot detect the supply temperature

increase, or (c) where the supply sensor is incorrectly placed – ie.

on the wrong pipe or on the

return of a system with very long runs.

The problem must be identified and corrective action taken.

If the target supply temperature slowly and continually decreases

after the boilers have been shut down, it indicates that the supply

temperature is hotter than the target temperature. This can happen

in systems with high mass boilers where the flow has been stopped

without using the heat demand input to the control, and convection

from the still hot boiler continues to heat the supply sensor. If the

heat demand input is used to shut the system down, the control will

ignore the sensor reading during the off cycle.

Overheating of buildings in warm weather will occur where minimum boiler temperatures are

required, unless the building has either a mixing system to reduce system supply water

temperatures to below boiler minimums, or some sort of room temperature control and zoning

system. Zone controls from tekmar, when used in these applications, will provide room

temperature feedback information to this control, allowing it to shift the heating curve for

maximum comfort and energy savings.

Typical Minimum Boiler Operating Temperatures: • Steel Tube Boilers …140

°

to 180

°

F (60

°

to 82

°

C) • Cast Iron Boilers …130

°

to 150

°

F (54

°

to 66

°

C) • Copper Tube Boilers …105

°

to

150

°

F (41

°

to 66

°

C) • Condensing or Electric Boilers …Off

Note: If the control is being operated in the setpoint mode and a boiler minimum setting is

selected, the user will be unable to program a setpoint lower than the minimum temperature

plus 1/2 of the Boiler Differential setting. If the minimum dial is set higher than the setpoint

less 1/2 the Boiler Differential, the setpoint will automatically be raised as the dial is turned

up. If the dial is then turned back down, the setpoint will have to be re-programmed.

Outdoor air temperature

Supply water temperature

50

(10)

30

(-1)

10

(-12)

-10

°

F

(-23)

°

C

110

(43)

70

(21)

70

(21)

90

(32)

210

(99)

170

(77)

150

(65)

130

(54)

190

(88)

3.6 3.0 2.4 2.0

0.8

0.4

1.0

0.6

90

(32)

50

°

F

(10)

°

C

Heating

Curve

1.2

Minimum Supply

Setting 130

°

F

WWSD

Point

70

°

F

1.6