S.p.A.

TE470/TE480 Instruction

Manual

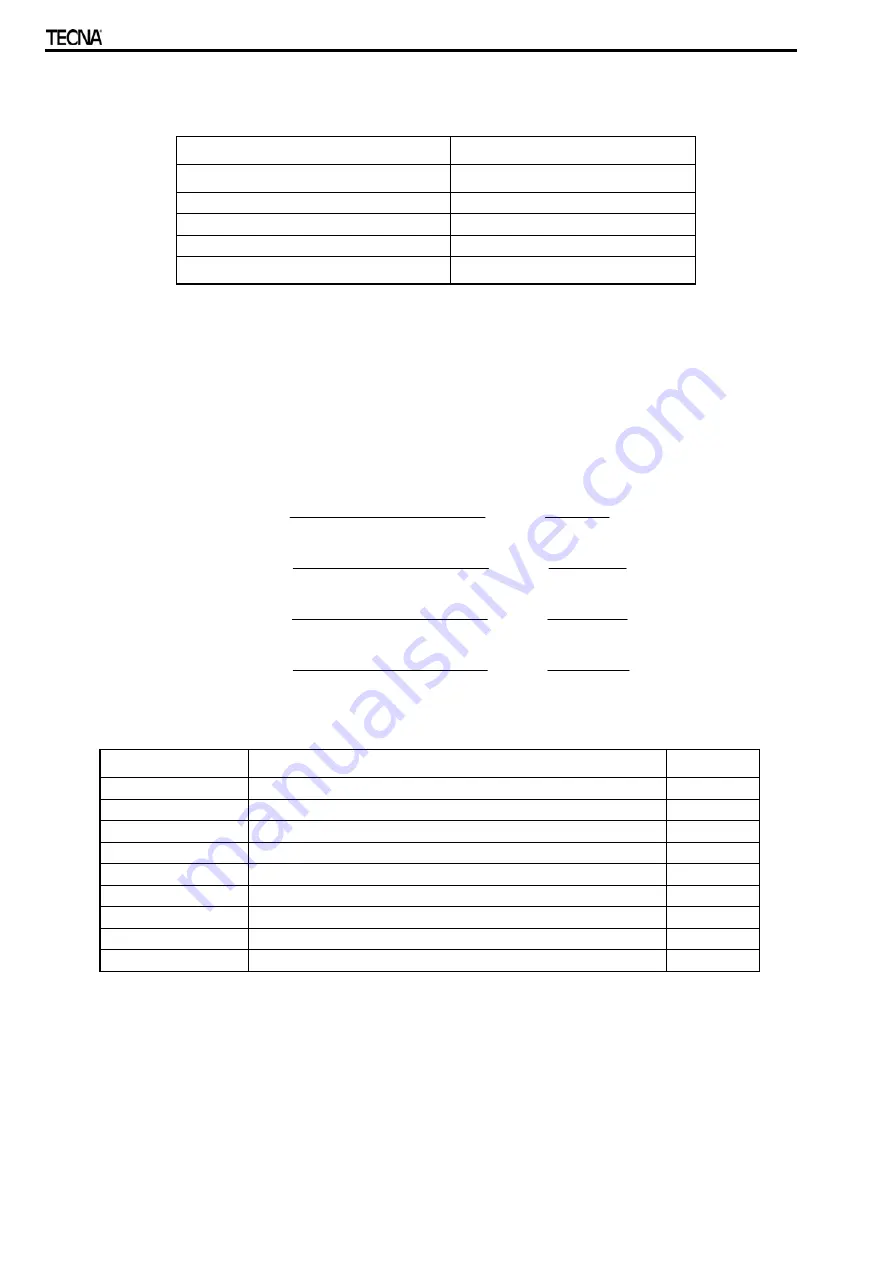

Example:

Welding tests have determined that the electrode life corresponds to 4000 welding spots, and that the following

currents values are necessary at different moments of the electrodes life

SPOTS PERFORMED

REQUIRED CURRENT

0 (initial electrodes diameter)

15 kA

700 17.8

kA

1800 19.5

kA

3000 20.2

kA

4000 (end electrodes diameter)

20.7 kA

For each segment, it is then possible to calculate both the duration (expressed in welding spots) and the percent

increment.

Please, notice that the percent increment must always be calculated referring to the beginning of the considered

segment.

spots

700

=

0

-

700

=

1

segment

of

Duration

spots

1100

=

700

-

1800

=

2

segment

of

Duration

spots

1200

=

1800

-

3000

=

3

segment

of

Duration

spots

1000

=

3000

-

4000

=

4

segment

of

Duration

%

19

100

15

15

8

.

17

100

1

%

rent

initialcur

rent

initialcur

endcurrent

segment

Change

%

10

100

8

.

17

8

.

17

5

.

19

100

2

%

rent

initialcur

rent

initialcur

endcurrent

segment

Change

%

4

100

5

.

19

5

.

19

2

.

20

100

3

%

rent

initialcur

rent

initialcur

endcurrent

segment

Change

%

3

100

2

.

20

2

.

20

8

.

20

100

4

%

rent

initialcur

rent

initialcur

enecurrent

segment

Change

The following parameters are set in the

SETUP MENU

:

PARAMETER PARAMETER

DESCRIPTION

VALUE

TOTAL STEPS

Number of segments per stepper function

4

SPOTS 1

Number of spots of the first segment

700

INCREMENT 1

Increment percent of first segment

19%

SPOTS 2

Number of spots of the second segment

1100

INCREMENT 2

Increment percent of second segment

10%

SPOTS 3

Number of spots of the third segment

1200

INCREMENT 3

Increment percent of third segment

4%

SPOTS 4

Number of spots of the fourth segment

1000

INCREMENT 4

Increment percent of fourth segment

3%

The welding program must be set in order to carry out the first welding spot, that is with an adjustment enabling

to obtain the necessary current with the starting electrodes diameter: 15 kA.

28/52