2-5

EO18-33003A

2. MAJOR UNIT REPLACEMENT

2.2 REPLACING THE MOTOR

2.2.2

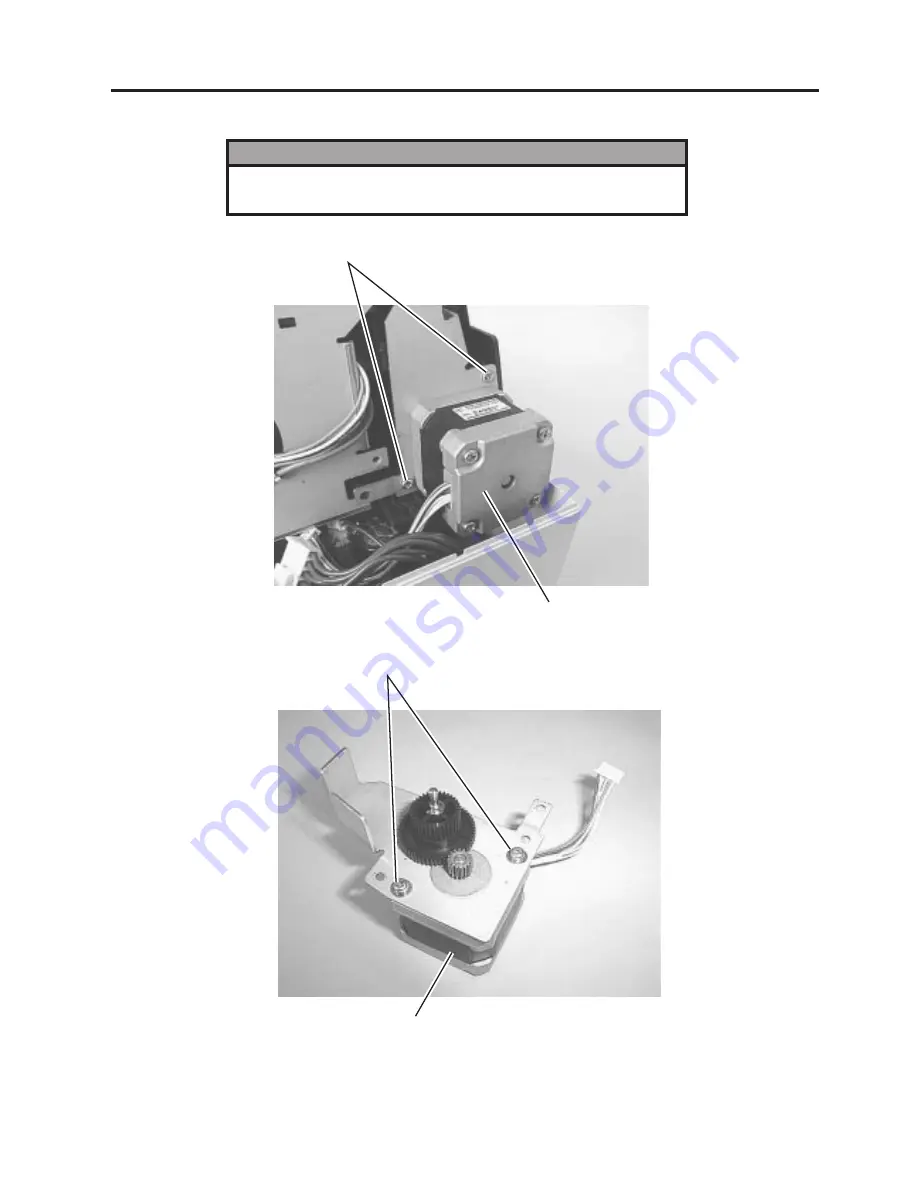

Stepping Motor

Fig. 2-6

2) Remove the two SMW-3x6 screws to detach the stepping motor.

3) Replace the stepping motor with a new one, and then reassemble in the reverse order of removal.

Fig. 2-7

PT-3x10 Screw

Stepping Motor Ass’y

SMW-3x6 Screw

Stepping Motor

1) Remove the two PT-3x10 screws to detach the stepping motor ass’y.

WARNING!

Be careful not to get burned when handling the stepping motor

since it becomes very hot while printing.

Summary of Contents for B-450 SERIES

Page 3: ......

Page 4: ...PRINTED IN JAPAN EO0 33003A...

Page 5: ...TEC Thermal Printer B 450 QQ SERIES Owner s Manual...

Page 31: ...13 1 EO1 33006 APPENDIX APPENDIX APPENDIX ASCII Code Chart Font Sample Barcode Sample...

Page 33: ......

Page 34: ...PRINTED IN JAPAN EO1 33006 E...

Page 35: ...TEC Label Printer B 450 HS QQ SERIES Owner s Manual...

Page 64: ...13 1 EO1 33019 APPENDIX APPENDIX APPENDIX ASCII Code Chart Font Sample Barcode Sample...

Page 66: ......

Page 67: ......

Page 68: ...PRINTED IN JAPAN EO1 33019 E...

Page 95: ......

Page 96: ...PRINTED IN JAPAN EO10 33003A...

Page 220: ......

Page 221: ......

Page 222: ...PRINTED IN JAPAN EO18 33003A...