5.

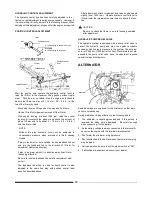

Treat antifreeze carefully so that it may not remove paint

from the cylinder block.

6.

Any antifreeze solution (antifreeze and water), even if it is

permanent antifreeze, should not be used for more than 2

years.

7.

Confirm that there are no leak from the hose connections or

cylinder head gasket.

8.

Antifreeze with proper density to suit the climate in your

area should be used.

9.

When antifreeze is used over a long period in winter, mea-

sure the specific gravity frequently.

NOTE

Consult your dealer concerning detergent and antifreeze.

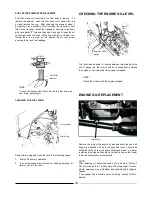

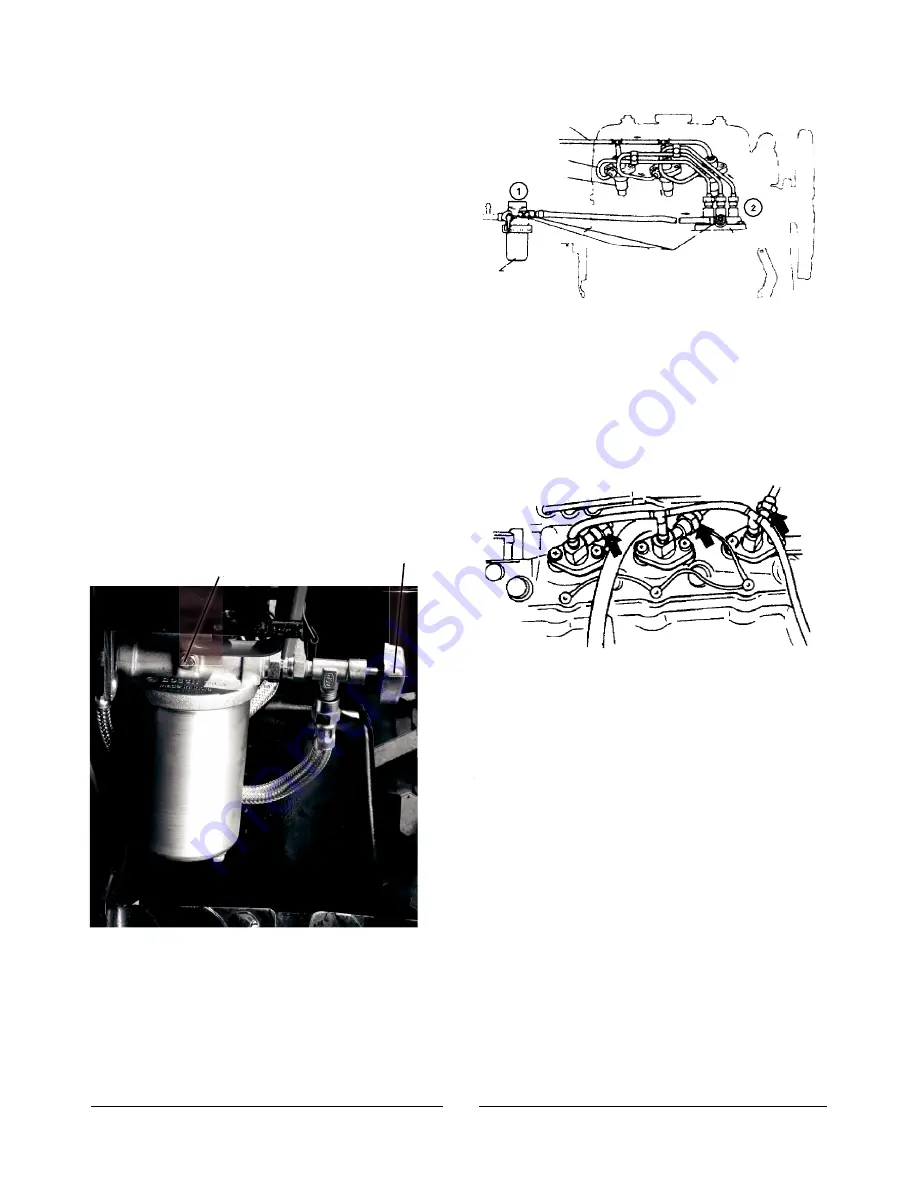

FUEL

PIPE AIR

BLEEDING

Overflow pipe

Injection pipe

Nozzle holder

Air vent screw

Fuel

filter

NOTE

Injection pump

With this operation, the engine should start, but if not,

bleed the injection pipe.

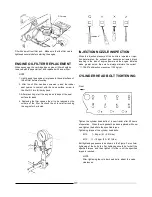

FUEL

SYSTEM AIR

BLEEDING

If fuel is exhausted and the engine stops or when the fuel filter

element is cleaned, air is induced into the fuel line. In such

case, the fuel system must be bled after refilling the fuel tank.

If

air remains in the fuel line, the engine cannot be started.

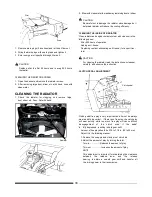

FUEL

PIPE AIR

BLEEDING

FUEL

FILTER AIR

BLEEDING

Air Bleeding Screw

Fuel cock

Loosen the nut of the injection nozzle as shown above and

shift the throttle lever to high speed position.

Then, start the

engine by operating the starter motor and make sure the fuel

is discharged properly at the loosened nozzle connection.

Tighten the nut to the specified torque. Start the engine

according to the steps given in "OPERATING

THE

TRACTOR".

NOTE

Unless air is completely bled, the engine cannot be

started; in such case, perform air bleeding again to let

the

remaining air completely out of the system.

Fill the fuel tank.

Loosen No. 1 air vent screw shown in the above photo until no

air is noticed in the fuel flow and then tighten up No. 1 air vent

screw.

Then loosen No. 2 air vent screw until no air is noticed in the

fuel and then tighten up No. 2, the air vent screw.

29

Summary of Contents for VST 818

Page 2: ......

Page 16: ...SECTION 2 EXTERNAL VIEW AND NOMENCLATURE OF EACH PART The above photos show TARAL VST 818 6 ...

Page 35: ...25 ...

Page 36: ...GREASING DIAGRAM Greasing Nipple Greasing Nipple Greasing Nipple 26 ...

Page 45: ...PROPER BATTERY MAINTENANCE AND TIPS FOR SAFETY 35 ...

Page 53: ...SECTION 8 WIRING DIAGRAM 43 ...

Page 58: ......

Page 59: ......