SECTION 5

REGULAR MAINTENANCE GUIDE

To keep your tractor operating in the top condition and to

assure

its proper performance and reliability for a long period of

time,

periodic inspection is indispensable. If your tractor is not

periodically serviced, the result will be such that its perfor-

mance and operating life will be reduced.

Also a major break-

down is more likely to occur, which will entail much more

expense what you would pay for regular maintenance.

Maintenance and servicing are very important, however, the

procedure is very simple. Carry out daily checking, greasing

and periodic service by carefully following the instructions given

in

this manual. In addition to daily inspection the following ser-

vicing must be carried out:

NOTE

The tractor should always be kept clean. Before greasing

or removing the oil pan plug and filter cap, be sure to wipe

the surface clean. When using tools for repairing inside the

engine, transmission, fuel tank or hydraulic unit, clean the

tools before use. Be careful especially when refueling. If

dust or water gets in the fuel, engine trouble will be experi-

enced, resulting in loss of power and the unexpected

necessity of parts replacement.

The tractor should be ser-

viced indoors where there is plenty of room and it is as

clean as possible.

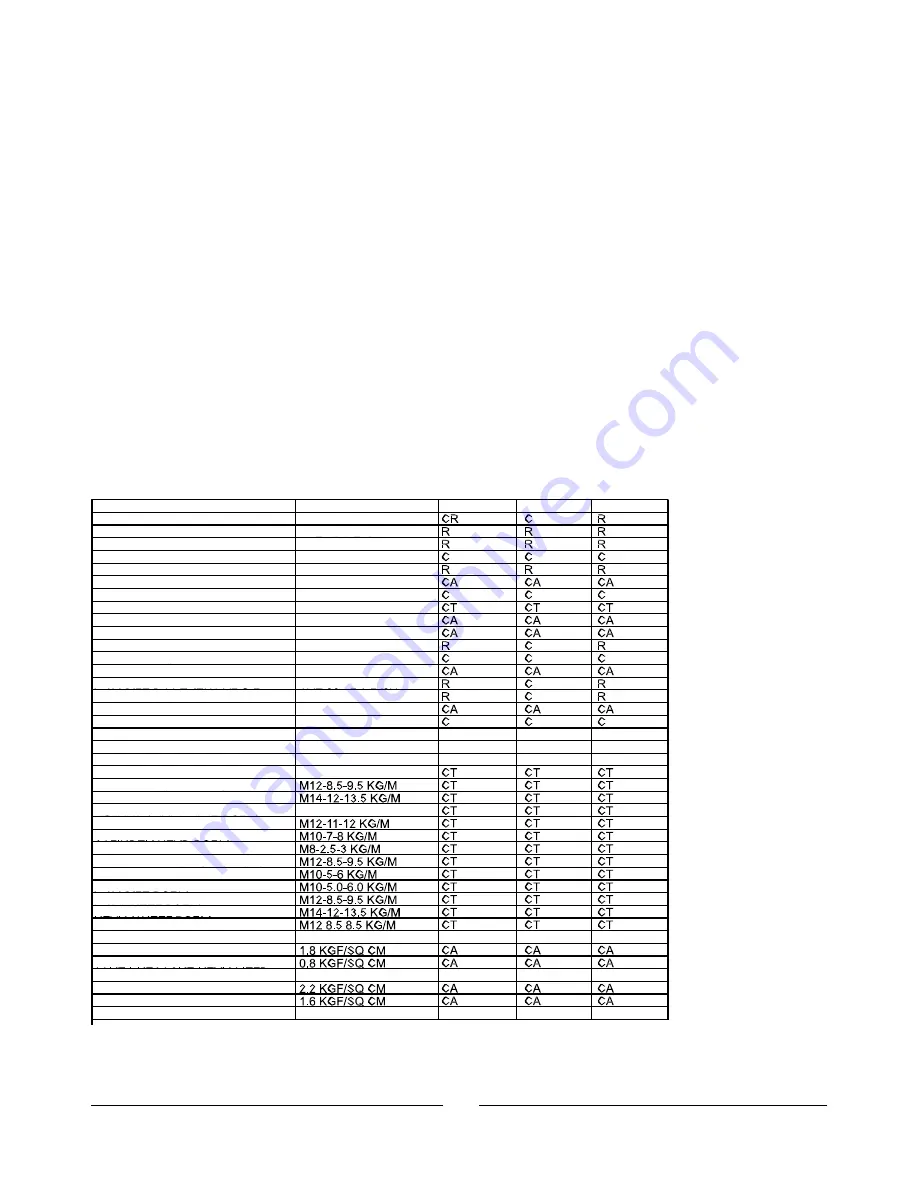

SERVICE SCHEDULE

Observe the following service schedule.

This service schedule

is applied to tractors which are operated under normal condi-

tions. When your tractor is frequently operated in muddy

places,

greasing must be carried out more frequently and

1. Service

2. Service

3. Service

50 hours / 30 days

150 hours / 90 days

250 hours / 150 days

when the tractor is often operated in dusty places, clean the air

cleaner element and fuel filter more frequently. Extra servicing

must be carried out according to particular situation.

SERVICE SCHEDULE CHART

AIR CLEANER

Check daily.

50 HRS/1st Service

150 HRS/2nd Service

250 HRS/3rd Service

ENGINE OIL

SAE 40-3 Liters

ENGINE OIL

FILTER

FUEL

FILTER BOWL

FUEL

FILTER ELEMENT

FAN BELT

TENSION

RADIATOR COOLANT

BATTERY

LEADS

BRAKE PEDAL

FREE PLAY

CLUTCH PEDAL

FREE PLAY

TRANSMISSION OIL

HYDRAULIC OIL

FILTER

FRT

HUB END PLAY

FRT

AXLE DIFFERANTIAL

OIL

SAE 90-12 Liters

SAE 90-2.5 Liters

TAPPET

CLEARANCE

DASH BOARD EQUIPMENT

OPERATIONS

RETIGHTEN ALL

FASENERS

AS APPLICABLE

STEERING LINKAGE

ENGINE MOUNTING BOLT

ENGINE MOUNTING BOLT

CYCLINDER HEAD BOLTS

CYCLINDER HEAD BOLTS

RADIATOR MOUNTING BOLTS

DRAG

ARM MTG BOLTS NUTS

GEAR BOX MOUNTING BOLTS

FRT

AXLE BOLTS

FRT

WHEEL

BOLTS

REAR WHEEL

BOLTS

ENGINE CLUTCH HOUSING BOLTS

TYRE PRESSURE FRT-FIELD

TYRE PRESSURE REAR-FIELD

TYRE PRESSURE FRT-ROAD

TYRE PRESSURE REAR-ROAD

R=REPLACE

CT= CHECK &

TIGHTEN

C=CHECK

CR= CLEAN & REPLACE

CA= CHECK &

ADJUST

BEYOND 450HRS REPEAT

THE CYCLE EVERY

100 HRS.

22

Summary of Contents for VST 818

Page 2: ......

Page 16: ...SECTION 2 EXTERNAL VIEW AND NOMENCLATURE OF EACH PART The above photos show TARAL VST 818 6 ...

Page 35: ...25 ...

Page 36: ...GREASING DIAGRAM Greasing Nipple Greasing Nipple Greasing Nipple 26 ...

Page 45: ...PROPER BATTERY MAINTENANCE AND TIPS FOR SAFETY 35 ...

Page 53: ...SECTION 8 WIRING DIAGRAM 43 ...

Page 58: ......

Page 59: ......