NOTE

In cold weather, check the specific gravity of the antifreeze

water mixture, if necessary replenish to the required level.

4.

Tightening nuts and bolts

Tighten

all nuts and bolts because vibration is always

noticed when the tractor is operated.

At the same time,

check the ballast weight bolts for tightness.

5.

Greasing

See "Greasing diagram".

6.

Check the front hub for end-play.

7.

Wash the fuel filter.

8.

For conventional batteries: Check the electrolyte in the bat-

tery, replenish if necessary.

2. SERVICE ( 150 hours of operation)

1.

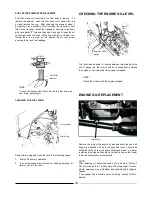

Replacing the engine oil

The engine oil should be replaced at the first 50 hours ser-

vice and again replaced after another 50 hours of operation.

Thereafter, replace the oil every 100 hours of operation.

2.

Replace the engine oil filter with a new one.

3.

For conventional batteries: Check the battery electrolyte for

its specific gravity.

4.

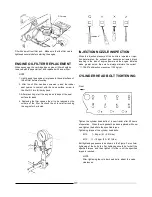

Clean the fuel filter.

NOTE

Carry it out at the same time as DAILY

INSPECTION.

3. SERVICE ( 250 hours of operation)

Carry out as follows along with DAILY

INSPECTION, and

repeat 2nd service.

1.

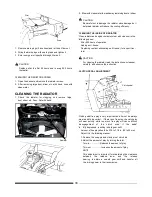

Replace transmission case oil.

2.

Clean the hydraulic oil filter.

3.

Replace the oil In the front axle differential case and the

front gear case of the 4-wheel drive tractor.

24

Summary of Contents for VST 818

Page 2: ......

Page 16: ...SECTION 2 EXTERNAL VIEW AND NOMENCLATURE OF EACH PART The above photos show TARAL VST 818 6 ...

Page 35: ...25 ...

Page 36: ...GREASING DIAGRAM Greasing Nipple Greasing Nipple Greasing Nipple 26 ...

Page 45: ...PROPER BATTERY MAINTENANCE AND TIPS FOR SAFETY 35 ...

Page 53: ...SECTION 8 WIRING DIAGRAM 43 ...

Page 58: ......

Page 59: ......