Care and maintenance

User guide

120

Cleaning the housing

Clean the printer housing with mild detergent (use a dishwashing

agent, if necessary, or a plastic cleaning agent) and a soft lint-free

cloth.

Do not use abrasive cleaners. Never use solvents.

Cleaning the interior

Remove paper and dust with a soft brush.

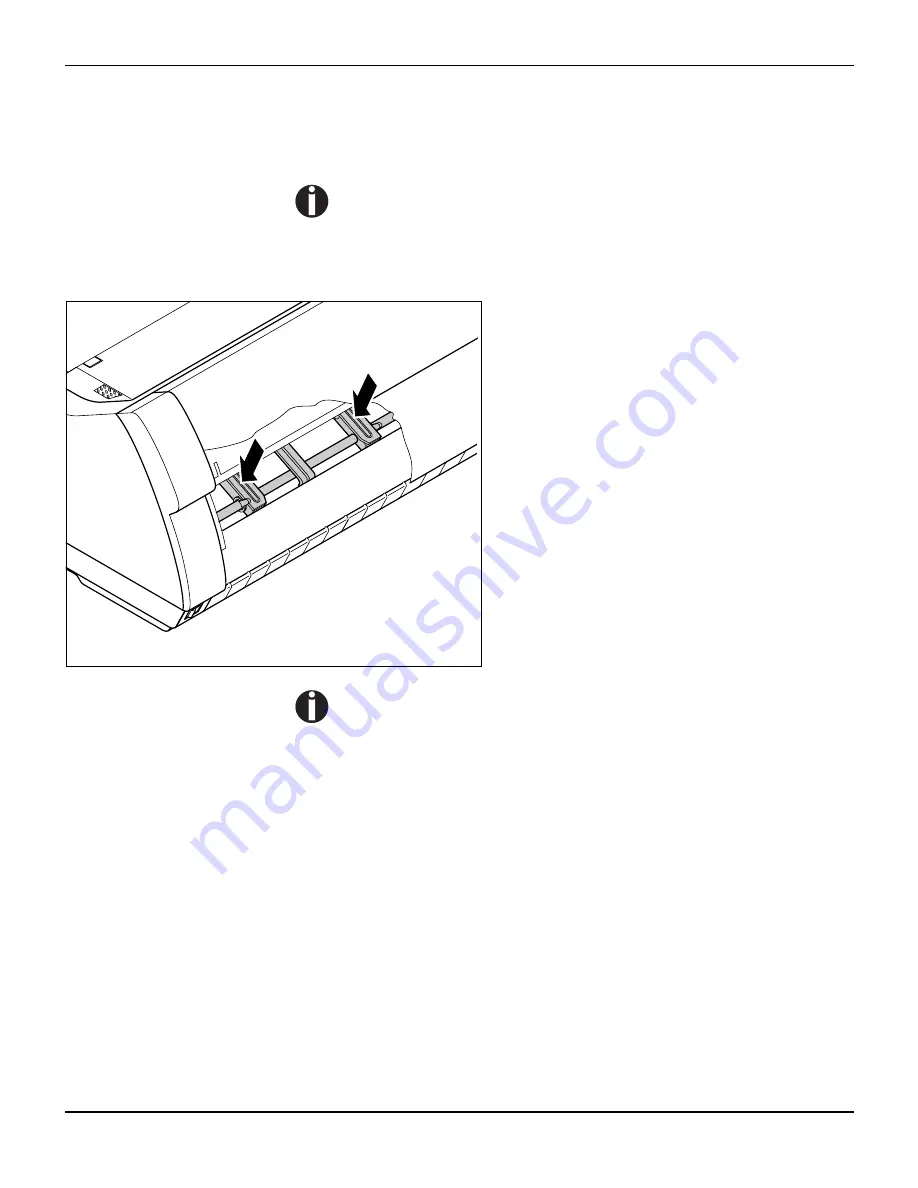

Check that any paper has been removed from

the tractors.

For optimal function of the print head the interior of the printer

has to be as dust free as possible. Clean the interior with a

vacuum cleaner if necessary.