Safety Precautions

5

Chapter 1

1

2

3

4

5

6

7

8

9

10

11

12

RR05

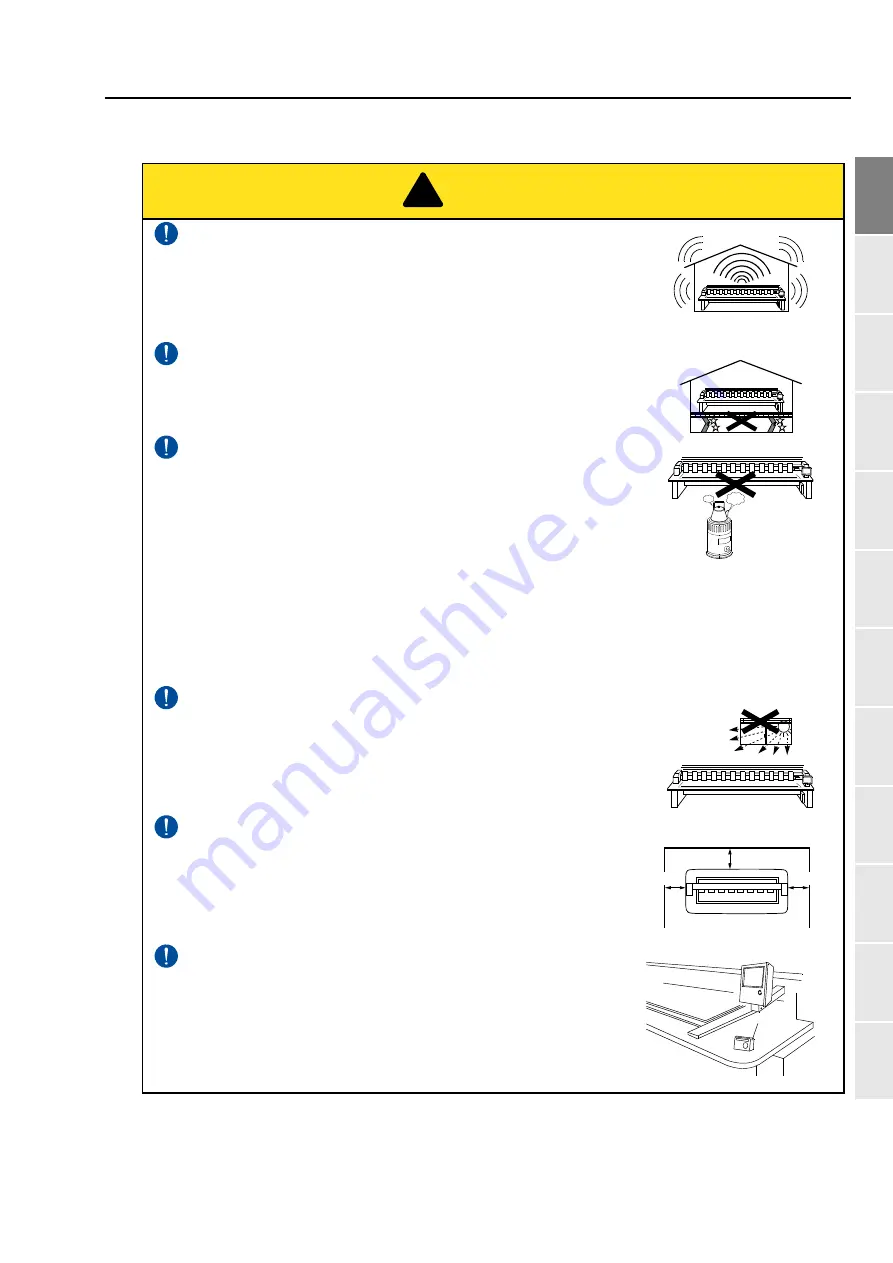

Prevent the operation noise in the environment.

This machine is designed to reduce noise during operation. To

improve the sound insulation performance in a factory still more, use

the interior finish materials which show high sound insulating

performance for the walls, ceiling, and floor of the factory.

Install the machine on a sturdy floor.

The floor structure must be strong enough to bear the machine

weight (indicated on the spec. plate).

Avoid dust and moisture.

Since dust and moisture lead to dirt and rust on the machine, use the

machine in an environment of facility of air conditioner, and clean the

working place periodically. Use caution not to expose the machine to

direct wind from the air conditioner so that embroidery threads do not

become disheveled.

Humidity:

30 to 95% RH (relative humidity) without condensation

Ambient temperature:

5 to 40°C (during operation), -10 to 60°C (during storage)

Avoid direct sunlight.

If the machine is exposed to direct sunlight over an extended period

of time, the machine body may be discolored or deformed. Put

curtains or shades to the site to prevent the machine from direct

sunlight.

Provide enough space for maintenance.

Taking account of workability when maintaining and inspecting the

machine, provide 50 cm or more working area to right, left and rear

directions of the machine against obstacles such as walls.

Pay attention to interference of radio wave.

Although the machine is designed not to affect radio wave

interference to other equipments, there could be cases where it

causes interference depending on operation environment and type of

other equipment. If such problems arise, install the equipment with a

space from the machine as big as possible.

!

CAUTION

50 cm

50 cm

50 cm

Summary of Contents for TLMX Series

Page 23: ...Inspection before starting work 8 Chapter 1 ...

Page 59: ...Attachment 44 Chapter 2 ...

Page 113: ...Embroidery starts 98 Chapter 4 ...

Page 145: ...Operation and setting for embroidering 130 Chapter 5 2 Select the value 3 RR05 ...

Page 209: ...Other functions that must be remembered 194 Chapter 6 ...

Page 231: ...To resister frame position 216 Chapter 7 ...