GB.COMPACTAHSK.210520

Registered design. The company reserves the right to make design changes without prior notice.

30 www.swegon.com

INSTALLATION

FUNCTIONS

*FUNCTIONS*

TEMPERATURE

AIR FLOW/PRESSURE

FILTER

OPERATION

HEATING

COOLING

IN/OUTPUTS

IQnomic Plus

ALL YEAR COMFORT

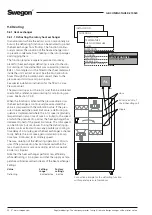

Connection principle for the defrosting function

with separate pressure transducer.

+

-

Nipple

Hose

Extract air duct of

the air handling unit

9.6 Heating

9.6.1 Heat exchanger

9.6.1.1 Defrosting the rotary heat exchanger

In environments where the extract air can occasionally be

humid, the defrosting function can be activated to protect

the heat exchanger from frosting. The function continu-

ously monitors the condition of the heat exchanger rotor

to prevent condensate from freezing in the rotor passages

and clogging them.

The function requires a separate pressure transducer,

preset for heat exchanger defrosting, is wired to the con-

trol unit inputs for external BUS communication (Internal

BUS-1). Two nipples must be fitted to the sheet metal wall

inside the unit’s extract air duct. See the illustration. Run

hoses through the insulation and connect them to the

pressure sensor’sminus and plus nipples.

See special installation instruction for the TBLZ-1-23-aa

Pressure sensor.

The pressure drop across the rotor must then be calibrated

to establish a reference pressure drop for monitoring pur-

poses. See Section 7.4.3.

When the function is activated the pressure drop across

the heat exchanger is continuously measured and the

value is compared with the calibration value. If the pres-

sure drop exceeds the preset limit value, a defrosting se-

quence is implemented where the rotor speed is gradually

ramped down (ramp time of max. 4 minutes) to the speed

at which the pressure drop across the heat exchanger has

decreased to half of the preset limit value. The rotor speed

can be 0.5 rpm but not slower. During the defrosting op-

eration, warm extract air thaws any possible ice coating. A

time delay of 4 minutes gives the heat exchanger a chance

to dry, before the rotor once again is ramped up (ramp

time max. 4 minutes) to its ordinary speed.

The max. duration of the defrosting operation is 30 min-

utes. If the pressure drop has not decreased within this

max. duration on six occasions during a 24-hour period,

an alarm is tripped.

Note that the heat exchanger performs less efficiently

while defrosting is in progress and that the supply air tem-

perature will decrease downstream of the heat exchanger.

Settings:

Value

Setting

Factory

range settings

Defrosting

Inactive/active Inactive

*HEAT*

HEAT EXCHANGER

HEATING BOOST