TROUBLESHOOTING

25

AVOID ELECTRIC SHOCK.

Permit only qualified electrical technicians to open

electrical enclosures, to perform electrical checks or to perform tests with the

power supply connected and wiring exposed. Failure to observe this warning

can result in serious injury or death.

AVOID ELECTRIC SHOCK.

Disconnect the power to the compressor before

troubleshooting the electrical components.

AVOID INJURY FROM BURNS.

During operation, some surfaces under the

compressor’s cover become hot. Allow the compressor to cool for ½ hour after

shutdown before removing the cover for maintenance.

PRESERVE YOUR WARRANTY.

Modification to equipment without the

consent of the manufacturer will void the warranty.

Compressor Capsule

Compressor motor checks for winding continuity, resistance and grounding will isolate most

motor electrical problems. When the checks indicate a faulty compressor, a replacement

is needed. Contact a Service Center.

Winding Continuity, Grounding and Resistance Checks

Tools required: Ohmmeter or multimeter

#2 Phillips screwdriver

The following electrical measurements to check the compressor motor may be made either at

the compressor terminals or at the motor contactor.

1.

Disconnect the power to the compressor.

2.

Remove the cover, side panels and rear panel from the compressor.

3.

Remove the terminal box cover from the side of the compressor motor to expose the three

terminals T

1,

T

2

and T

3

. It is not necessary to remove the wires from their terminals.

4.

With an ohmmeter, check the resistance across pairs of compressor terminals. Line to line

motor resistance for the F-70H compressor capsule should be about 2.27 ± 10% ohms, at

room temperature. Line to line motor resistance for the F-70L compressor capsule should

be about 0.56 ± 10% ohms at room temperature.

If there is no continuity, there is an open

circuit in the motor windings. Consult a Service Center. If the resistance is less, there is a

short circuit in the motor. Consult a Service Center.

5.

With the ohmmeter, check for continuity between the motor windings and one of the

unpainted tubes entering the compressor capsule. Use the three compressor terminals and

one of the copper tubes from the compressor. If there is continuity, there is a short circuit to

ground in the motor windings. Consult a Service Center.

Summary of Contents for F-70H

Page 2: ......

Page 8: ...4 This page is intentionally blank...

Page 10: ...6 This page is intentionally blank...

Page 12: ...8 This page is intentionally blank...

Page 14: ...10 This page is intentionally blank...

Page 28: ...24 This page is intentionally blank...

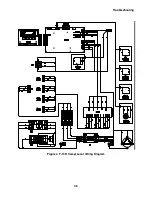

Page 40: ...Troubleshooting 36 Figure 4 F 70H Compressor Wiring Diagram...

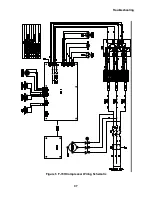

Page 41: ...Troubleshooting 37 Figure 5 F 70H Compressor Wiring Schematic...

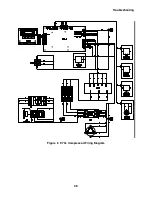

Page 42: ...Troubleshooting 38 Figure 6 F 70L Compressor Wiring Diagram...

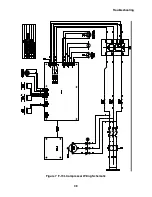

Page 43: ...Troubleshooting 39 Figure 7 F 70L Compressor Wiring Schematic...