Maintenance

14

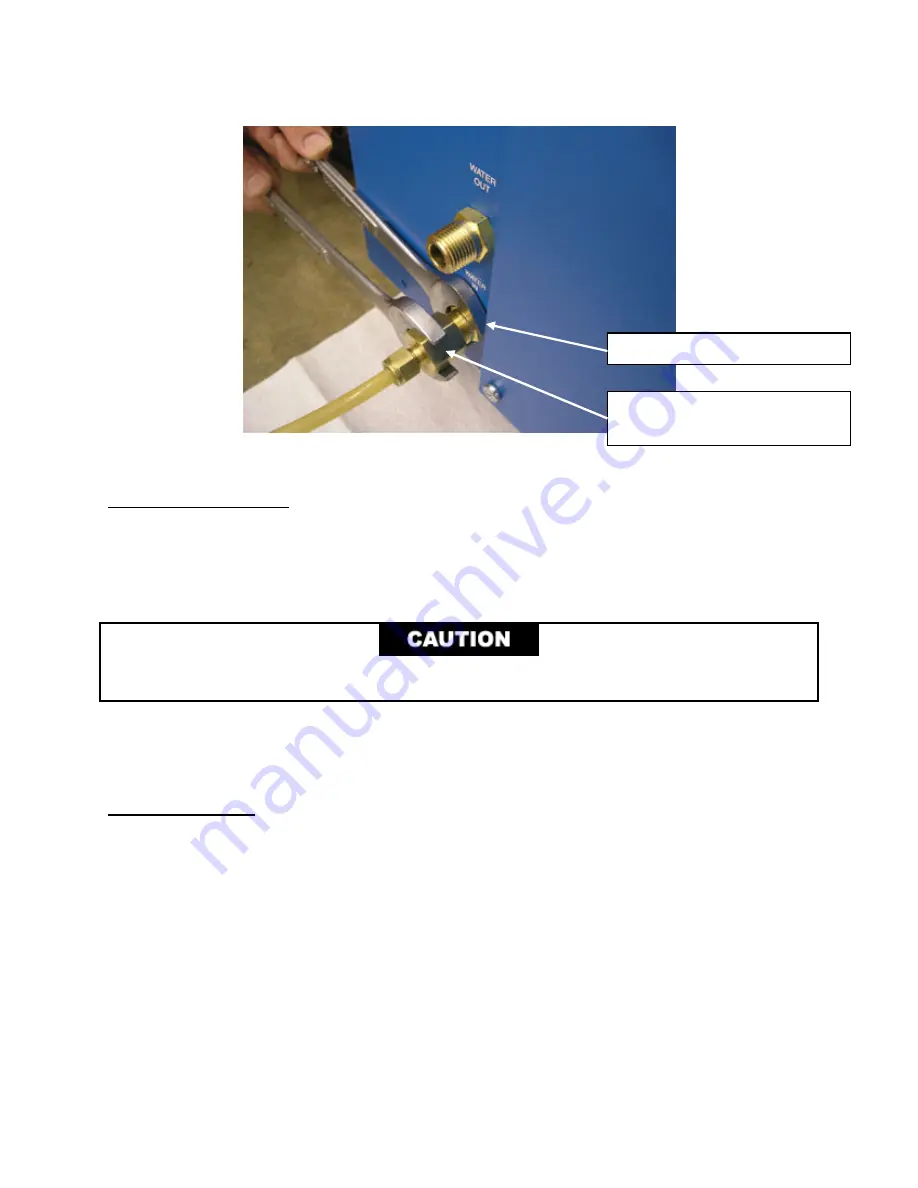

Figure 2 Connect and Remove the Water Lines

Adsorber Replacement

Part required: Adsorber, P/N F300138A

Tools required: #2 Phillips screwdriver

Open-end wrenches, 1", 1 1/8", 1 3/16"

Snoop

®

AVOID EQUIPMENT FAILURE OR CONTAMINATION.

Use SHIG adsorber P/N F300138A

only. Use of non-SHIG spare parts will void the warranty.

The compressor’s adsorber should be replaced every 30,000 operating hours (40 months).

The used adsorber has no salvage or repair value. Venting the compressor is not required

when replacing the adsorber because the gas couplings are self-sealing.

Adsorber Removal

1.

Stop the compressor and disconnect the power to the compressor.

2.

Disconnect the high pressure (supply) gas line from the helium high pressure coupling on

the compressor. Screw a dust plug into the disconnected gas line. Use two wrenches.

NOTE

Always hold the stationary nut on the gas line coupling with one wrench while

turning the moveable coupling with the other wrench.

3.

Remove the compressor’s cover panel.

4.

Disconnect the self-sealing coupling on the inlet side of the adsorber. Use two wrenches.

Hold jam nut with one wrench

Turn water line coupling with

the other wrench

Summary of Contents for F-70H

Page 2: ......

Page 8: ...4 This page is intentionally blank...

Page 10: ...6 This page is intentionally blank...

Page 12: ...8 This page is intentionally blank...

Page 14: ...10 This page is intentionally blank...

Page 28: ...24 This page is intentionally blank...

Page 40: ...Troubleshooting 36 Figure 4 F 70H Compressor Wiring Diagram...

Page 41: ...Troubleshooting 37 Figure 5 F 70H Compressor Wiring Schematic...

Page 42: ...Troubleshooting 38 Figure 6 F 70L Compressor Wiring Diagram...

Page 43: ...Troubleshooting 39 Figure 7 F 70L Compressor Wiring Schematic...