Section 4

OPERATION

19

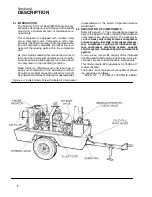

4.1 GENERAL

While Sullair has built into this compressor a compre-

hensive array of controls and indicators to assure

you that it is operating properly, you will want to rec-

ognize and interpret the reading which will call for

service or indicate the beginning of a malfunction.

Before starting your Sullair compressor, read this

section thoroughly and familiarize yourself with the

controls and indicators --- their purpose, location and

use.

4.2 PURPOSE OF CONTROLS

CONTROL OR INDICATOR

PURPOSE

TOGGLE IGNITION SWITCH

Turn this switch to the

“

on” position to energize the electri-

cal system of the compressor. Turn to the

“

off” position to

shut the compressor down. This switch is located on the in-

strument panel.

STARTER BUTTON

Push this button along with the override button to start the

compressor. Release the starter switch as soon as the en-

gine is engaged, but hold the override button for 5 to 10 sec-

onds or until the engine oil pressure reaches 20 psig (1.4

bar).

OVERRIDE BUTTON

Located on the instrument panel, it is used to bypass the oil

pressure switch when starting the engine. It must be

pressed simultaneously with pushing the starter button.

AIR PRESSURE GAUGE

Continually monitors the pressure inside the receiver sump

at various load and unload conditions.

HOURMETER

Indicates the accumulated hours of operation. Useful for

planning and logging service schedules.

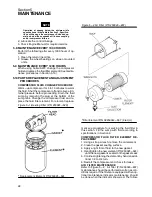

FLUID LEVEL SIGHT GLASS

Monitors the fluid level in the sump. Proper level is always

centered in the sight glass. Check the level when the com-

pressor is shut down and on level ground.

COMPRESSOR DISCHARGE TEMPERATURE

Opens the electrical circuit to shut down the compres---

SWITCH

sor when the discharge temperature reaches a specific

value (see Section 3, Specifications).

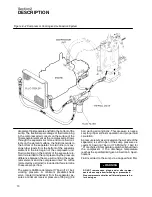

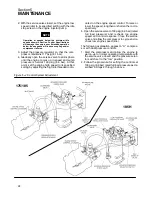

THERMAL VALVE

Functions as a temperature regulator directing the com-

pressor fluid either to the cooler or to the compressor unit.

MINIMUM PRESSURE/CHECK VALVE

Maintains the minimum of 55 psig (3.8 bar) in the compres-

sor sump. This valve restricts receiver air discharge from re-

ceiver/sump when pressure falls to 55 psig (3.8 bar); how-

ever, full flow is allowed at normal operating pressures.

PRESSURE RELIEF VALVE

Opens sump pressure to the atmosphere should pressure

inside the sump exceed 140 psig (9.7 bar) or 175 psig (12.1

bar) on 185H.

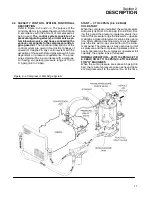

AIR INLET VALVE

Regulates the amount of air allowed to enter the air inlet

valve. This regulation is determined by a pressure signal

from the pressure regulator.

PRESSURE REGULATOR (S)

Allows a pressure signal to reach the engine speed control

cylinder and the air inlet valve to control air delivery accord-

ing to demand.

Summary of Contents for 175

Page 6: ...NOTES ...

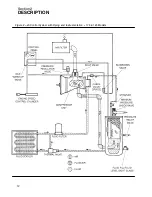

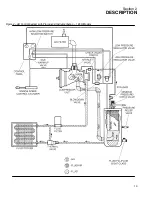

Page 22: ...Section 2 DESCRIPTION 16 Figure 2 7 Electrical System ...

Page 52: ...Section 7 ILLUSTRATIONS AND PARTS LIST 46 7 4A RADIATOR COMPRESSOR FLUID SYSTEM 175 MODELS ...

Page 54: ...Section 7 ILLUSTRATIONS AND PARTS LIST 48 7 4A RADIATOR COMPRESSOR FLUID SYSTEM 175 MODELS ...

Page 78: ...Section 7 ILLUSTRATIONS AND PARTS LIST 72 7 9B ELECTRICAL PARTS 185 185H MODELS ...

Page 80: ...Section 7 ILLUSTRATIONS AND PARTS LIST 74 7 10 INSTRUMENT PANEL PARTS ALL MODELS ...

Page 82: ...Section 7 ILLUSTRATIONS AND PARTS LIST 76 7 11A AIR INLET AND EXHAUST 175 MODELS ...

Page 84: ...Section 7 ILLUSTRATIONS AND PARTS LIST 78 7 11B AIR INLET AND EXHAUST 185 185H MODELS ...

Page 86: ...Section 7 ILLUSTRATIONS AND PARTS LIST 80 7 12 FUEL TANK CONNECTIONS ALL MODELS ...

Page 88: ...Section 7 ILLUSTRATIONS AND PARTS LIST 82 7 13A CANOPY PARTS 175 MODELS ...

Page 90: ...Section 7 ILLUSTRATIONS AND PARTS LIST 84 7 13B CANOPY PARTS 185 185H MODELS ...

Page 92: ...Section 7 ILLUSTRATIONS AND PARTS LIST 86 7 14 DECALS ...

Page 94: ...Section 7 ILLUSTRATIONS AND PARTS LIST 88 7 14 DECALS ...

Page 96: ...Section 7 ILLUSTRATIONS AND PARTS LIST 90 7 14 DECALS ...

Page 99: ......