Section 6

NOISE CONTROL

32

6. ANNUAL INSPECTIONS FOR PROPER OPERATION OF ALL SYSTEMS.

In addition to other instructions in the Operator’s Manual, at least annually, operate compressor and inspect

to make sure all systems are operating properly and that engine runs at rated speed and pressure.

DO NOT

operate malfunctioning or improperly adjusted compressor. Repair or adjust, per instructions in Operator’s

Manual, as required.

Maintenance

Performed

By

Location

Date

Maintenance

Performed

By

Location

Date

DDDDDDDDDDDDDDDDD

Summary of Contents for 175

Page 6: ...NOTES ...

Page 22: ...Section 2 DESCRIPTION 16 Figure 2 7 Electrical System ...

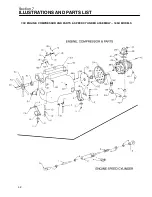

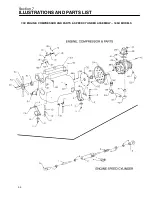

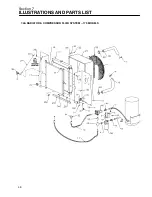

Page 52: ...Section 7 ILLUSTRATIONS AND PARTS LIST 46 7 4A RADIATOR COMPRESSOR FLUID SYSTEM 175 MODELS ...

Page 54: ...Section 7 ILLUSTRATIONS AND PARTS LIST 48 7 4A RADIATOR COMPRESSOR FLUID SYSTEM 175 MODELS ...

Page 78: ...Section 7 ILLUSTRATIONS AND PARTS LIST 72 7 9B ELECTRICAL PARTS 185 185H MODELS ...

Page 80: ...Section 7 ILLUSTRATIONS AND PARTS LIST 74 7 10 INSTRUMENT PANEL PARTS ALL MODELS ...

Page 82: ...Section 7 ILLUSTRATIONS AND PARTS LIST 76 7 11A AIR INLET AND EXHAUST 175 MODELS ...

Page 84: ...Section 7 ILLUSTRATIONS AND PARTS LIST 78 7 11B AIR INLET AND EXHAUST 185 185H MODELS ...

Page 86: ...Section 7 ILLUSTRATIONS AND PARTS LIST 80 7 12 FUEL TANK CONNECTIONS ALL MODELS ...

Page 88: ...Section 7 ILLUSTRATIONS AND PARTS LIST 82 7 13A CANOPY PARTS 175 MODELS ...

Page 90: ...Section 7 ILLUSTRATIONS AND PARTS LIST 84 7 13B CANOPY PARTS 185 185H MODELS ...

Page 92: ...Section 7 ILLUSTRATIONS AND PARTS LIST 86 7 14 DECALS ...

Page 94: ...Section 7 ILLUSTRATIONS AND PARTS LIST 88 7 14 DECALS ...

Page 96: ...Section 7 ILLUSTRATIONS AND PARTS LIST 90 7 14 DECALS ...

Page 99: ......