Section 2

DESCRIPTION

14

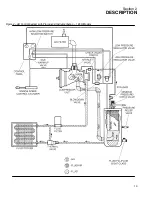

Figure 2---5 Air Inlet System

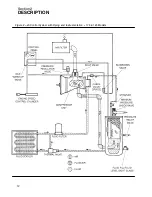

the inlet valve remains fully open for maximum air

output. The engine will continue to run at full speed

during this phase of operation.

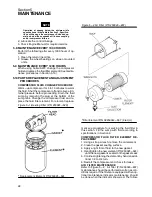

MODULATION -- 100 TO 110 PSIG (6.9 TO 7.6

BAR) OR 150 TO 165 PSIG (10.3 TO 11.4 BAR)

FOR “H” MACHINES

Should less than the rated capacity of air be used,

the service line pressure will rise above 100 psig (6.9

bar) low or single pressure rating, 150 psig (10.3

bar) dual or high pressure rating. The pressure reg-

ulating valve gradually opens, applying pressure to

the inlet valve piston and speed control cylinder.

This causes the inlet valve to partially close and re-

duces the speed of the engine. As the pressure in-

creases, the inlet valve piston will further close the

inlet valve and continue reducing the speed until it

reaches a pre---set idle speed. Now as air demand

increases, the sump pressure will fall below the 110

psig (7.6 bar) or 165 psig (11.4 bar) for “H” ma-

chines.

The pressure regulating valve will close, the air inlet

valve will fully open and the engine will once again

run at a pre---set full load speed.

Between the pressure regulating valve and inlet

valve, a small orifice is installed which vents a small

amount of air to the atmosphere, when the pressure

regulating valve is open. This allows variance of air

output to match air demand. The orifice also bleeds

any accumulated moisture from the regulator.

SHUTDOWN

The blowdown valve is normally closed. Upon shut-

down, the back pressure in the compressor inlet

signals the blowdown valve to vent the sump pres-

sure to the atmosphere. After the sump pressure

has vented, the idle warm---up valve will automati-

cally reset from normal operation mode to start

mode.

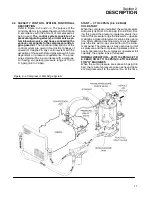

2.7 AIR INLET SYSTEM, FUNCTIONAL DESCRIP-

TION

Refer to Figure 2---5. The air inlet system consists of

two air filters

, a

compressor air inlet valve

and

in-

terconnecting piping

to the engine and compres-

sor.

The air filters are 2---stage dry element---type filters.

These filters are capable of cleaning extremely dirty

air. However, in such cases, frequent checks of the

air filter will be required.

See Section 5 for Air Filter Maintenance Procedures.

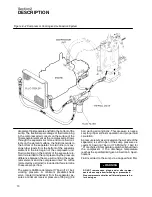

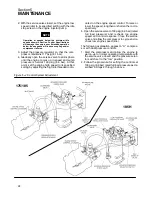

2.8 INSTRUMENT PANEL GROUP, FUNCTIONAL DE-

SCRIPTION

Refer to Figure 2---6. The instrument panel group

consists of a heavy gauge panel containing an

air

pressure gauge, hourmeter, starter pushbutton,

toggle ignition switch, circuit override button,

circuit breaker, warning light

for

alternator mal-

function,

and

idle warm--up button

. A

high--low

pressure selector switch

is located on the panel

for 185H compressors.

Refer to Figure 2---6 for locations of the following in-

dicators and controls:

S

The

air pressure gauge

continually monitors the

sump pressure at various load or unload conditions.

Summary of Contents for 175

Page 6: ...NOTES ...

Page 22: ...Section 2 DESCRIPTION 16 Figure 2 7 Electrical System ...

Page 52: ...Section 7 ILLUSTRATIONS AND PARTS LIST 46 7 4A RADIATOR COMPRESSOR FLUID SYSTEM 175 MODELS ...

Page 54: ...Section 7 ILLUSTRATIONS AND PARTS LIST 48 7 4A RADIATOR COMPRESSOR FLUID SYSTEM 175 MODELS ...

Page 78: ...Section 7 ILLUSTRATIONS AND PARTS LIST 72 7 9B ELECTRICAL PARTS 185 185H MODELS ...

Page 80: ...Section 7 ILLUSTRATIONS AND PARTS LIST 74 7 10 INSTRUMENT PANEL PARTS ALL MODELS ...

Page 82: ...Section 7 ILLUSTRATIONS AND PARTS LIST 76 7 11A AIR INLET AND EXHAUST 175 MODELS ...

Page 84: ...Section 7 ILLUSTRATIONS AND PARTS LIST 78 7 11B AIR INLET AND EXHAUST 185 185H MODELS ...

Page 86: ...Section 7 ILLUSTRATIONS AND PARTS LIST 80 7 12 FUEL TANK CONNECTIONS ALL MODELS ...

Page 88: ...Section 7 ILLUSTRATIONS AND PARTS LIST 82 7 13A CANOPY PARTS 175 MODELS ...

Page 90: ...Section 7 ILLUSTRATIONS AND PARTS LIST 84 7 13B CANOPY PARTS 185 185H MODELS ...

Page 92: ...Section 7 ILLUSTRATIONS AND PARTS LIST 86 7 14 DECALS ...

Page 94: ...Section 7 ILLUSTRATIONS AND PARTS LIST 88 7 14 DECALS ...

Page 96: ...Section 7 ILLUSTRATIONS AND PARTS LIST 90 7 14 DECALS ...

Page 99: ......