-

54

-

© STULZ GmbH, Hamburg

-

54

-

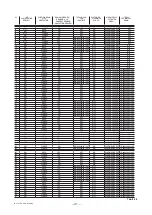

11.2 Table of alarms and signals

code displayed

con-

troller

remote

term.*

causes

solution

action

reset

display (H)

alarm

relay

reset

relay (H)

H

P

H

EH

E102

over-current at the electrodes;

probable electrode malfunction

or water conductivity tempo-

rarily too high (especially when

starting after a short stop)

1. check the operation of the drain

electrovalve

2. check the seal of the fill electrovalve

when not energised

3. drain part of the water and re-start.

total

shut-

down

total

shut-

down

not

available

active

not

available

EL

E103

power not available; with the

machine on no steam is

produced

1. with the machine off and disconnected

from the mains, check the internal

electrical connections.

total

shut-

down

total

shut-

down

not

available

active

not

available

EC

E105

high supply water conductivity 1. check limit set for b6;

2. turn the machine off and clean

the water conductivity measuring

electrodes;

3. if the problem persists, change

the source of supply water or

install a suitable treatment system

(demineralisation, even partial).

N.B.: the problem will not be resolved

by softening the supply water.

-

total

shut-

down

not

available

active

not

available

EP

E113

excessive reduction in

production

1. cylinder completely depleted or

water with excessive foam. Perform

maintenance on the cylinder

total

shut-

down

machine

disabled

manual

active

manual

EF

E114

no water

1. check that the fill pipe from the mains

to the humidifier and the internal pipe

are not blocked or bent and that there

is sufficient pressure (0.1-0.8 MPa,

1-8 bar);

2. check the operation of the fill

electrovalve;

3. check that the steam outlet is not

working against excessive back

-pressure, preventing the flow of water

into the cylinder by gravity;

4. check that the steam outlet pipe is not

is choked and that there are no pockets

of condensate.

total

shut-

down

machine

disabled

automatic

when water

returns (see

par. 12.2.10)

active

automatic

when

water

returns

EA

E115

excessive foam in the cylinder

during boiling

the formation of foam is generally due to

the presence of surfactants in the water

(lubricants, solvents, detergents, water

treatment agents, softeners) or an

excessive concentration of dissolved salts:

1. drain the water supply lines

2. clean the cylinder

3. check for the presence of softeners

(in this case, use another type of water

or reduce the softening)

-

signal

only

manual

active

manual

E

C

E116

drain malfunction

check the drain circuits and the correct

operation of the drain electrovalve

total

shut-

down

machine

disabled

manual

active

manual

E

C

E131

high water conductivity

pre-alarm

check the conductivity of the supply water

if necessary, install a suitable treatment

system

N.B.: the problem will not be

resolved by softening the supply water.

-

signal

only

automat.

not

active

E-

E121

high humidity in the room

(high temp. for T control)

check the operation of the probe and the

limit set for parameter P2

-

signal

only

manual

active

auto

E

_

E122

low humidity in the room

(low temp. for T control)

check the operation of the probe and the

limit set for parameter P3

-

signal

only

manual

active

auto

E

=

E124

high outlet humidity

check the operation of the outlet

probe

-

signal

only

manual

active

auto