18

AFTER SALES SUPPORT

1300 886 649

AUS

MODEL: STR-PGGC75 PRODUCT CODE: 10288 09/2019

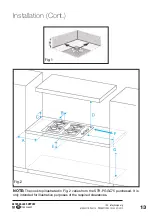

Installation (Cont.)

Installing the gas regulator

• When installing the gas regulator, ensure that its valve outlet thread

matches the thread of the gas connector.

• Use an appropriate sealant around the threads.

• Ensure that the gas regulator valve installation location is perpendicular.

• After installation, open the gas source switch and check the valve body

connections with soap and water for leaks.

Converting the gas regulator for use with LPG

This cooktop is fitted out for use with Natural Gas (NG). If it is to be used with

liquefied petroleum gas (LPG), the gas regulator valve has to be converted.

• Using special tools, open the cover of the gas regulator valve by turning it

anticlockwise (Fig. 11-A, page 19).

• Remove the adaptor from the top cover (Fig. 11-B).

• Pull out the adaptor, invert it and replace the top cover (Fig. 11-C).

• Invert the assembled adaptor’s top cover and replace the regulator valve

(Fig. 11-D).

NOTE:

Do not adjust the regulator valve body piece in the above procedure,

otherwise it will affect the performance parameters set in the factory.

WARNING:

• The regulator valve outlet pressure is set at the factory, please do not

adjust it in order to avoid the occurrence of safety accidents.

• If you find any abnormality of the regulator valve, stop using the appliance

and contact our after sales support centre for advice.

Do not attempt any

maintenance yourself

.

Table 1: Performance parameters

NG

LPG

Operating temperature

–20°C to 60°C

Inlet pressure setting

6 in.wc

11 in.wc

Outlet pressure

5±0.3 in.wc

10±0.5 in.wc

Inlet side screw

1/4 NPT

Outlet side screw

1/4 NPT