Ashby-MF Insert

33

If you notice a difference in the operation of the Stove,

first check to see if there has been a

change in the fuel you are burning.

If the fuel properties have significantly changed,

such as

the

fuel is very dirty, then making a change to the damper is correct.

However if the Stove needs cleaning,

changing the Damper may mask the fact that the stove is

getting plugged.

It is always a good idea to thoroughly clean your stove before making a

significant damper change.

If you experience problems adjusting the Stove during the Break-In Period, contact your

dealer.

Some chimney systems will fall outside the norm, for example, a chimney with excessive

draft or one with a long horizontal run.

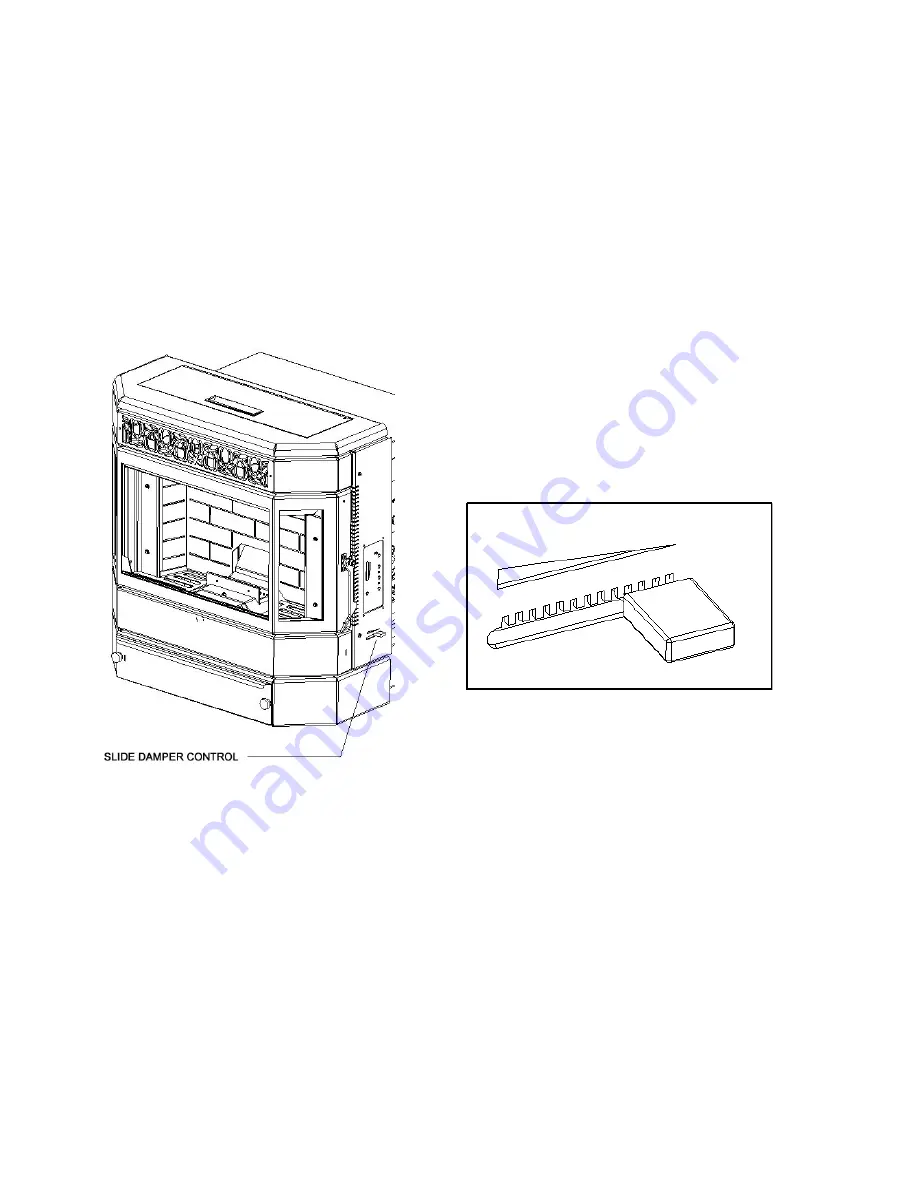

Figure 19 shows the location of the damper control

lever. The tabs and notches shown each represent

1/16”. See figure 20 on the following page and note

the location where the damper handle stops towards

the closed position and then note the location where

the damper stops towards the open position.

Figure 19

Flame Pattern Characteristics

Correct Flame Pattern -

Bright yellowish-white flame with a brisk movement, having sharp

pointed end tips extending up towards the Heat Exchange Tubes while forming a fan-like shape.

Small amounts of ash and some live sparks being blown out from the Burn Pot area is considered

normal operation.

Incorrect Flame Pattern -

Dark Orangish-Brown flame with a lazy movement, having black

smoky end tips curling up and over the Heat Exchange Tubes while forming a fireball-like shape.

Excessive black soot forming on the ceramic glass surface is a sign of very poor combustion (not

enough combustion air) and should not be overlooked.

At the other end of the spectrum; an extremely brisk flame which blows large pieces of live coal

out from the Burn Pot area and causes stubborn shiny black build-up on the glass (too much

combustion air) is also considered undesirable and requires the damper to be closed.