54

A.0500.351 – IM-TGH/07.02 EN (10/2015)

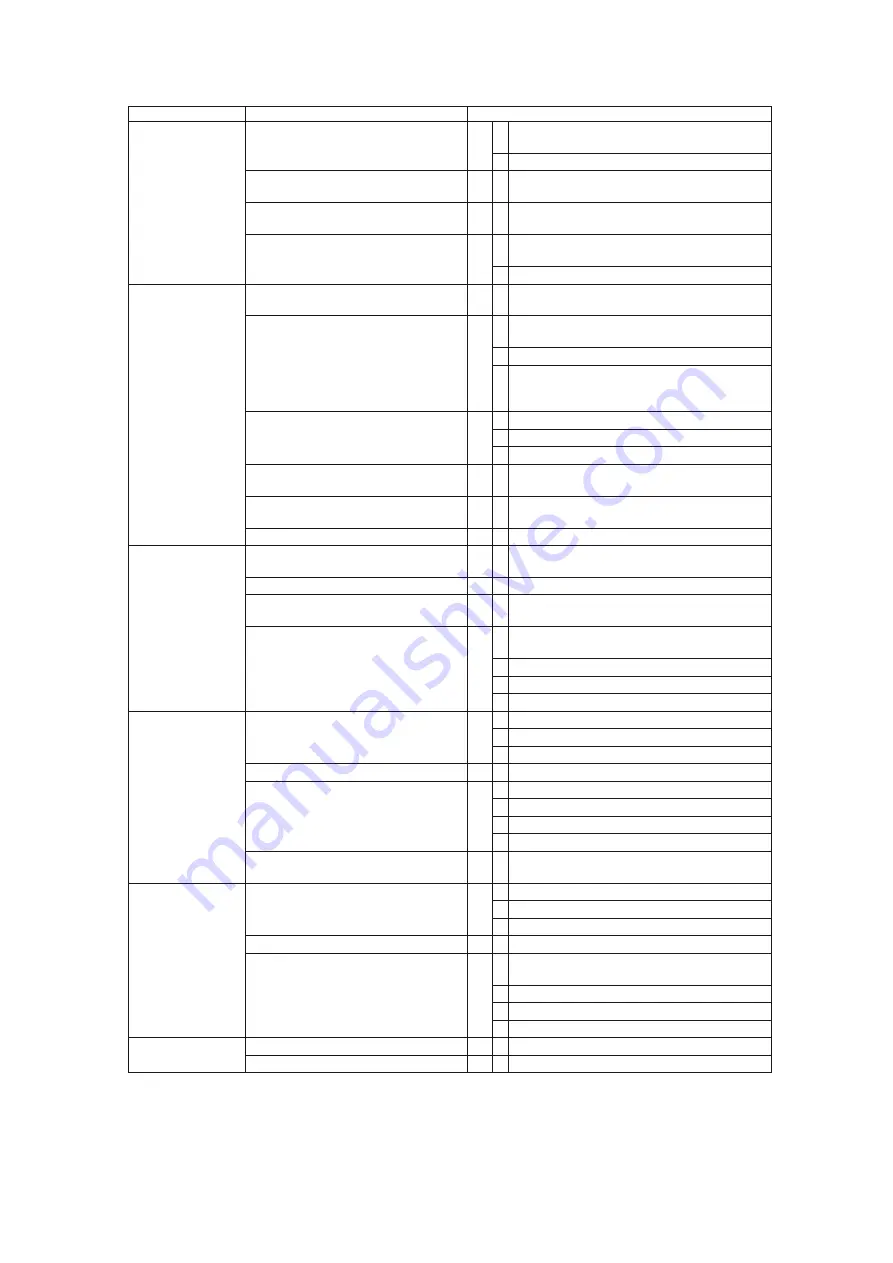

Symptom

Cause

Remedy

Not enough capacity Viscosity too low

17 • Increase pump speed.

Attention!

Do not exceed

maximum speed and check NPSHr.

• If necessary, install a larger pump.

•

• If pump is heated by means of heating jackets or

electrical heating, reduce the heating input.

Axial clearance

18 • Check axial clearance and correct.

See section 3.21 Maintenance instructions.

Gases come free

19 • Increase pump speed.

Attention!

Do not exceed

maximum speed and check NPSHr.

• Install a larger pump

Pump too noisy

Pump speed too high

20 • Reduce pump speed.

If necessary, install a larger pump.

Cavitation

21 • Reduce difference between pump and suction

tank level.

• Increase suction pipe diameter.

• Reduce length and simplify suction pipe (use as

few elbows and other fittings as possible).

Also see section 3.18 Installation.

Back pressure too high

22 • Increase pipe diameter.

• Reduce working pressure.

• Check accessories (filter, heat exchanger, etc.).

Coupling misalignment

23 • Check and correct alignment.

Also see section 3.18 Installation.

Vibration of base plate or pipings

24 • Make base plate heavier and/or fix base plate/

pipe work better.

Ball bearings damaged or worn

25 • Replace ball bearings.

Pump consumes

too much power or

becomes hot

Pump speed too high

26 • Reduce pump speed.

If necessary, install a larger pump.

Gland packing too tight

27 • Check or replace gland packing.

Coupling misalignment

28 • Check and correct alignment.

Also see section 3.18 Installation.

Viscosity too high

29 • Increase axial clearance.

See section 3.21 Maintenance instructions.

• Heat pump.

• Reduce pump speed.

• Increase discharge pipe diameter.

Rapid wear

Back pressure too high

30 • Increase pipe diameter.

• Reduce working pressure.

• Check accessories (filter, heat exchanger, etc.)

Solid matter in liquid

31 • Filter liquid.

Pump runs dry

32 • Correct liquid supply.

• Provide level switch or dry running protection.

• Heat up liquid.

• Stop or reduce air sucking.

Corrosion

33 • Change pump materials or application

parameters.

Motor overloading

Back pressure too high

34 • Increase pipe diameter.

• Reduce working pressure.

• Check accessories (filter, heat exchanger, etc.).

Gland packing too tight

35 • Check and replace gland packing.

Viscosity too high

36 • Increase axial clearance.

See section 3.21 Maintenance instructions.

• Heat pump.

• Reduce pump speed.

• Increase discharge pipe diameter.

Pump leak

Gland packing leaks excessively

37 • Check or replace gland packing.

Mechanical seal leaks

38 • Replace mechanical seal.

Summary of Contents for TG H15-50

Page 103: ...103 A 0500 351 IM TGH 07 00 EN 10 2015...

Page 105: ...105 A 0500 351 IM TGH 07 00 EN 10 2015...

Page 106: ...106 A 0500 351 IM TGH 07 00 EN 10 2015...

Page 107: ...107 A 0500 351 IM TGH 07 00 EN 10 2015...

Page 108: ...108 A 0500 351 IM TGH 07 00 EN 10 2015...

Page 109: ......