- 40 -

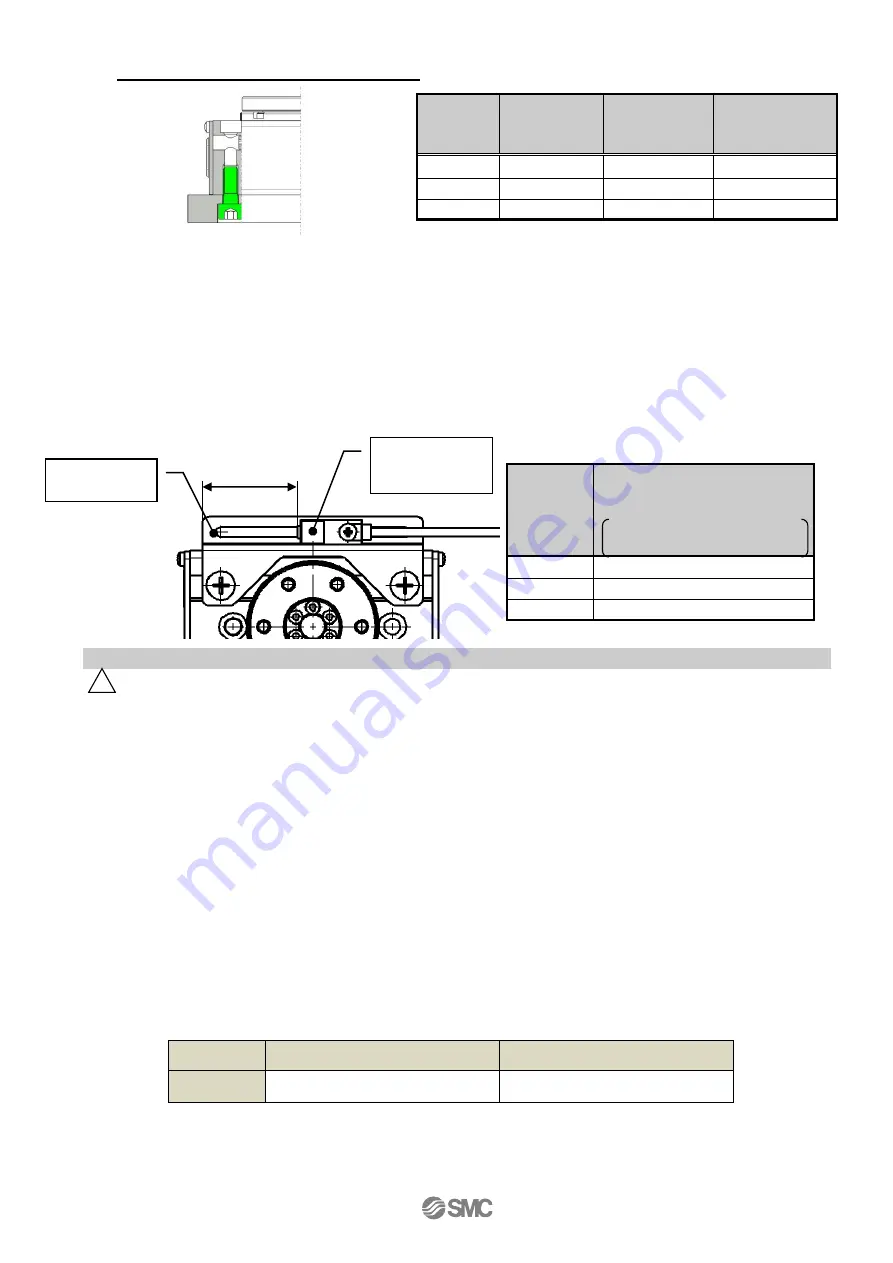

Rotary actuator mounting (tapped holes)

3. The mounting face has holes and slots for positioning. If required use them for accurate

positioning of the rotary actuator.

4. If it is necessary to operate the product when it is not energized, use the manual override

screws.

When the product is operated with the manual override screws, check the position of the manual

override of the table, and leave necessary space. Do not apply excessive torque to the manual override

screws that could lead to damage and malfunction of the product.

5. The proximity sensor for the return to origin for 360o type can be r/-30

o

.

If the position of the proximity sensor for return to origin is changed, the tightening torque

must be 0.6 +/-0.1

[

Nm

]

6.3 Handling

1. If an external guide is mounted, connect it so that impact and load will not be applied to it.

Use a freely moving connector (such as a coupling).

2. The positioning force should be set to 100% of the the initial value.

If the positioning force is set below the initial value, there may be variation in the cycle time, or an alarm

may be generated.

3. INP output signal

1) Positioning operation

When the product comes within the set range by step data [In position], output signal will be turned

on. Initial value: Set to [0.50] or higher.

2) Pushing operation

When the pushing force exceeds the [TriggerLV] value the INP ( In position) output signal is turned

on.

Please set the [Pushing force] and the [TriggerLV] within the specified range.

a. To ensure that the actuator pushes the workpiece by the inputted [pushing force], it is

recommended that the [TriggerLV] is set to the same value as the [pushing force].

b. When the [TriggerLV] and [pushing force] are set to be less than the lower limit of the specified

range, there is the possibility that the INP output signal will be switched on from the pushing

operation start position.

< Pushing force and trigger LV range >

Model

Set value of pushing force[%]

Set value of TriggerLV[%]

LER*

40~50

40~50

Part no.

Bolt

Max.

tightening

torque [Nm]

Max. thread

depth L[mm]

LER*10

M6×1

5.0

12

LER*30

M8×1.25

12.0

16

LER*50

M10×1.5

25.0

20

Part no.

L[mm]

(Default value)

Cable entry:

Basic type / Entry from the left

Between the sensor holder

end and Proximity sensor end

LER*10-1

31 / 31

LER*30-1

42 / 42

LER*50-1

51.5 / 51.5

! Caution

L

Proximity

sensor

assembly

Sensor

holder

Summary of Contents for LER Series

Page 3: ... 2 7 Troubleshooting 42 ...