E

.

The Function For 200 Point

39

entering the desired UCS.

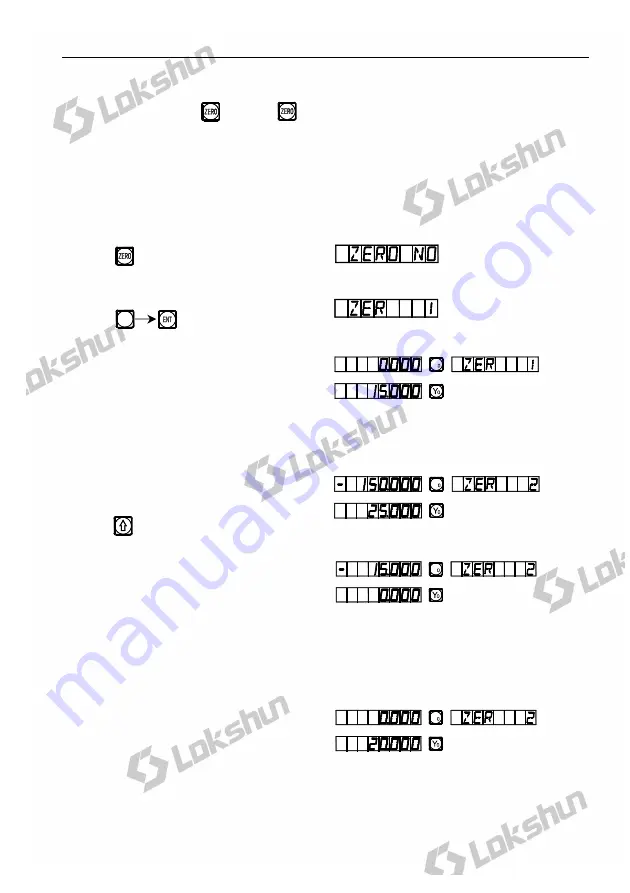

When using key just key and under the prompt “ZERO No” enter the

number of the desired UCS. For the related operations, the operator may refer to

“5 Absolute/relative/user coordinate display mode” under “

Ⅰ

.Usage” of “A. Basic

Function”.

We take the working piece shown in Fig. (1) as example.

1) Enter the display mode of the first UCS.

Key

2) Enter the number.

Key

3) Move the machine tool to Point A.

X axis display 0,

Y axis display 15.

4) Process Hole A.

5) Enter the display mode of the second

UCS.

Key

6) Move the working of the machine tool

to Point B

X axis display -15,

Y axis display 0.

7) Process Hole B

8) Move the machine tool to Point C.

X axis display 0,

Y axis display 20.

9) Process Hole C

1

X

X

X

X

Summary of Contents for SDS2MS

Page 4: ...Illustration of Panel and Keyboard 1...

Page 21: ...B Smooth R 13 B Smooth R Iran agent Tel 021 66 3939 00 Mob 0912 147 3023 www Sino ir...

Page 30: ...C Simple R 22 C Simple R Iran agent Tel 021 66 3939 00 Mob 0912 147 3023 www Sino ir...

Page 65: ...J N3 Function 57 J N3 Function Iran agent Tel 021 66 3939 00 Mob 0912 147 3023 www Sino ir...