Aoralscan 2 User Manual

SHNING 3D TECH Co.,Ltd Copyright

2019 All Rights Reserved

- 18 -

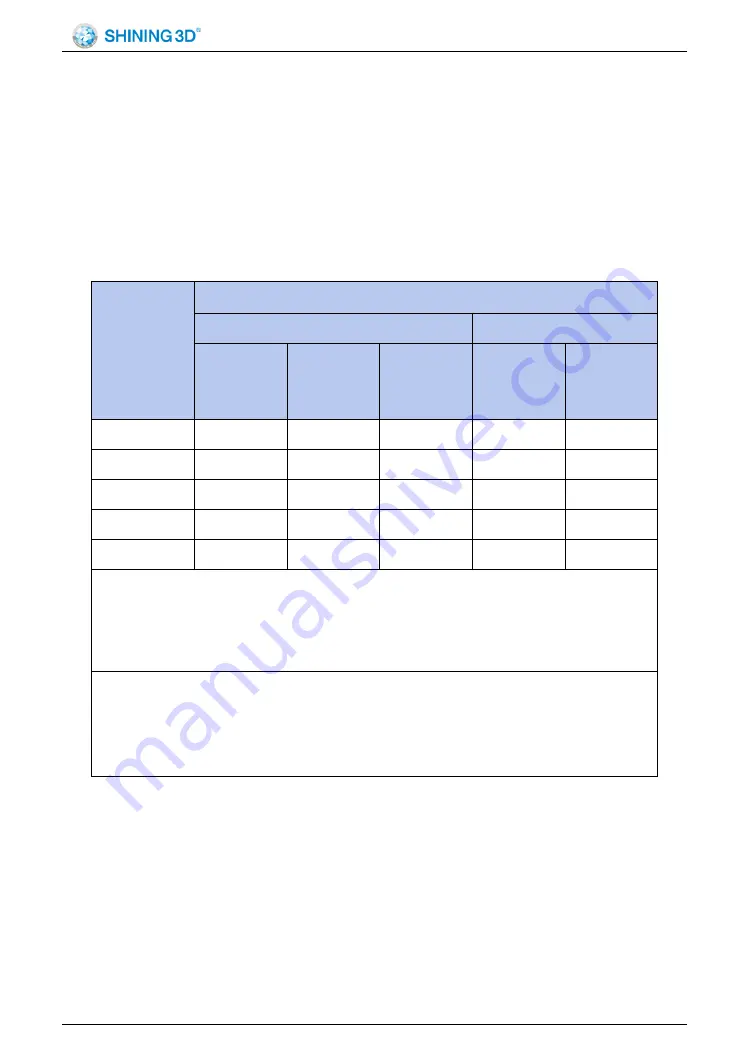

Separation distances

The

Aoralscan 2

is intended for use in the electromagnetic environment

in which radiated RF disturbances are controlled. The customer or the user of

the

Aoralscan 2

can help prevent electromagnetic interference by maintaining

a minimum distance between portable and mobile RF communications

equipment (transmitters) and the

Aoralscan 2

as recommended below,

according to the maximum output power of the communications equipment.

Rated

maximum

output

power of

transmitter

(W)

Separation distance according to frequency of transmitter

(

m)

IEC 60601-1-2 : 2007

IEC 60601-1-2 : 2014

150 kHz to

80 MHz

d

= 1.2

√P

80 MHz to

800 MHz

d

= 1.2

√P

800 MHz to

2.5 GHz

d

=

2.3

√P

150 kHz to

80 MHz

d

= 1.2

√P

80 MHz to

2.7 GHz

d

= 2.0

√P

0.01

0.12

0.12

0.23

0.12

0.20

0.1

0.38

0.38

0.73

0.38

0.63

1

1.2

1.2

2.3

1.2

2.0

10

3.8

3.8

7.3

3.8

6.3

100

12

12

23

12

20

For transmitters rated a maximum output power not listed above, the

recommended separation distance

d

in meters (m) can be estimated using the

equation applicable to the frequency of the transmitter, where

P

is the maximum

output power rating of the transmitter in watts (W) according to the transmitter

manufacturer.

NOTE 1:

At 80 MHz and 800 MHz, the separation distance for the higher frequency

range applies.

NOTE 2:

These guidelines may not apply in all situations. Electromagnetic

propagation is affected by absorption and reflection from structures, objects

and people.

Table 2-5 Recommended separation distances between portable and mobile RF

communications equipment and the

Aoralscan 2

The medical electrical equipment is suitable for the professional

healthcare environment per 60601-1-2:2014. It is suitable for use in physician

offices, clinics, hospitals, and other professional healthcare environments

except near HF surgical equipment and the RF shielded room of an ME

Summary of Contents for Aoralscan 2

Page 1: ...Aoralscan 2 IntraoralScan User Manual ...

Page 17: ...Aoralscan 2 User Manual SHNING 3D TECH Co Ltd Copyright 2019 All Rights Reserved 16 ...

Page 28: ...Aoralscan 2 User Manual SHNING 3D TECH Co Ltd Copyright 2019 All Rights Reserved 27 ...

Page 48: ...Aoralscan 2 User Manual SHNING 3D TECH Co Ltd Copyright 2019 All Rights Reserved 47 ...