32

Control section problem

Paper jam outside printer

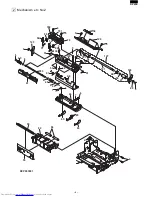

Paper feed mechanism

is defective

Clutch mechanism is

defective

Ribbon cassette not

inserted correctly

Ribbon cassette is defective

Foreign object in ribbon

drive mechanism or gear

is damaged.

Paper is not

transported at all

or erratically.

Paper feed pitch is

wrong.

Ribbon is not

transported.

PF armature does

not operate.

PF armature

operates.

Paper feed amount

is too large.

Check points

Countermeasure

Check the circuit hardware of the printer control

section and the connection cable to the printer.

Check for a jam in the external paper path.

Check for a problem in the external paper setting mechanism.

Check for locking due to foreign object or damaged gear.

Check whether the PF slip mechanism has enough force

for paper feed.

Check the PF latch for wear.

Check whether ribbon cassette is inserted correctly.

Turn ribbon cassette take-up knob in arrow direction and

check knob rotation and take-up action of the ribbon.

Turn motor gear clockwise by hand and check whether

the gear train moves.

If there is a problem, repair the printer

control section or replace connecting

cable.

If there is a paper jam, repair the paper

feed path.

If setting is incorrect, set the paper

properly.

If locked, remove foreign objects or

replace the gear if damaged.

If force is insufficient, replace the PF

slip mechanism.

If worn, replace any worn parts.

If not set properly, reinsert correctly.

Replace the ribbon cassette as necessary.

If not rotating, remove any foreign

objects. If the gear is damaged, replace

the gear.

Symptom

Condition

Cause

Paper feed problem

Ribbon feed problem