30

Motor does not

move.

Motor normal

Carriage operation

normal

Check points

Countermeasure

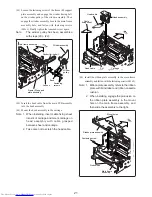

Remove carriage and check engaging condition of

carriage drive pin and pulley.

Check whether carriage rails (front and back) are

lubricated.

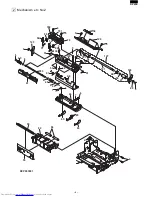

Measure voltage between pins 29 (+) and 24 (-) of

connector on main PCB assembly and verify that 5 V DC

is supplied.

Observe waveform of signal at pin 6 (HP), pin 8 (DP),

and pin 26 (RP) and check whether signal is normal.

Check circuit hardware of printer control section and

connection cable to printer.

Check FFC connection condition.

Check whether replacing print head assembly solves the

problem.

Note that if the printer control section is defective, the

head can be destroyed.

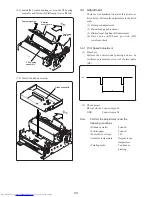

Verify that ribbon cassette is loaded correctly.

Measure voltage between pins 29 (+) and 24 (-) of

connector on main PCB assembly and verify that 5 V DC

is supplied.

Observe waveform of signal at pin 6 (HP), pin 8 (DP),

and pin 26 (RP) and check whether signal is normal.

If there is a phase shift, reseat the time

belt assembly.

Lubricate if not sufficiently

lubricated.

If not supplied, repair the printer control

section.

If signal is not normal, replace the main

PCB assembly.

If there is a problem, repair the printer

control section or replace the connecting

cable.

Reinsert FFC if disconnected.

If operation is normal, replace the print

head assembly.

If not correct, reinsert.

If not supplied, repair the printer control

section.

If signal is not normal, replace the main

PCB assembly.

Symptom

Condition

Cause

Carriage does not

move.

Carriage does not

stop.

Unit does not print

(all dots/specific

dots).

Timing belt assembly and

pulley phase shift

Carriage actuator problem

DP/HP/RP signal problem

Control section problem

Head FFC disconnected

Print head assembly

is defective

Ribbon cassette not

inserted properly

DP/HP/RP signal problem

Head movement problem

Print problem