15

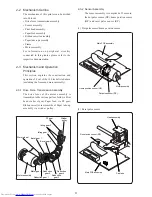

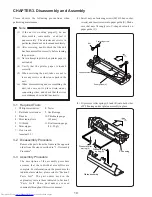

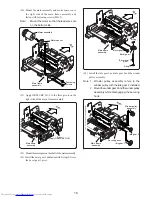

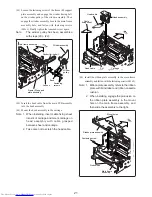

(24) Apply ORELUBE G-1/3 to the pivot of the pulley

drive assembly. Mount the carriage drive pulley and

fasten with E-ring (E2.5).

(25) Align the positions of the mounted carriage drive

pulley cutout and the cutout of the other carriage drive

pulley andmount timing belt assembly.

(26) Provisionally fasten the pulley drive assembly with

M3 washer and fastening screw (M3x5).

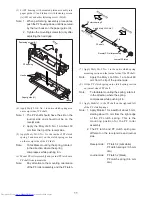

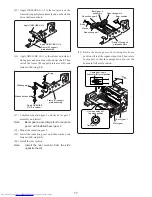

(27) Move the carriage drive pin to the center of the pulley

drive assembly, perform the tension adjustment to

determine the position of pulley drive plate assembly,

and fasten the assembly. Use a dial tension gauge

for the tension adjustment. When pushed with a force

of 30 gf, the timing belt displacement must be 2 mm.

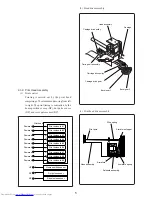

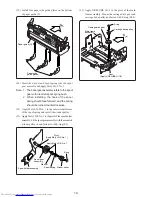

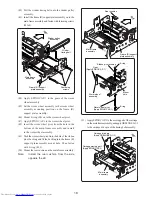

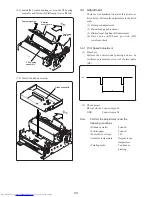

(28) Apply ORELUBE G-1/3 to the fastening boss of the

stamp lever plate in the paper guide (L) assembly and

to the three slits contacting the plate.

Note:

Paper guide (L) assembly refers to the

paper guide (L) with pressure rollers,

paper pressure sheet, 1-line validation

PCB assembly and validation guide plate

installed.

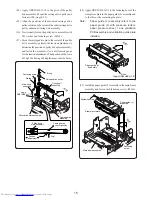

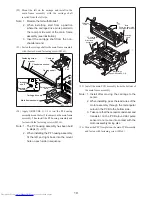

(29) Install the paper guide (L) assembly in the main frame

assembly and fasten with fastening screws (M3x6).

Rear

Main frame assembly

Stamp lever plate

Paper guide (L)

assembly

Fastening

screw

Fastening screw

Rear

Paper guide (L)

assembly

Boss

(Apply ORELUBE G-1/3)

Rear

Carriage drive pulley

Timing belt

assembly

Pulley drive plate assembly

Main frame

assembly

Carriage drive

assembly

E-ring

Fastening screw

Washer

2mm

30gf

Carriage drive

pin center position

Pulley drive

plate assembly

Position

adjustment

Apply

ORELUBE G-1/3