Maintenance and repair of the

eBee RTK

9.3 Full airframe and sensor inspection

Beyond the general airframe inspection that is performed before every flight, we

recommend that you perform a full airframe and sensor inspection regularly to

keep your drone in good operating condition.

Caution:

The autopilot, sensors and actuators within the Central

Body of the

eBee RTK

are specially calibrated and should only be

modified by your

eBee RTK

reseller. Opening the Central Body of the

eBee RTK

will void the warranty.

The inspection includes the following checks:

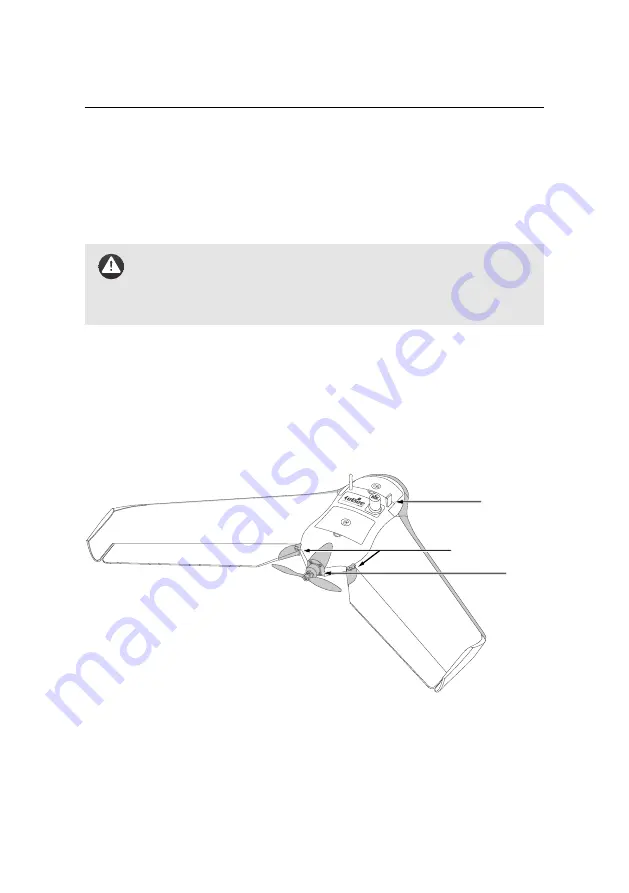

Check 1: Motor and Servos

The

eBee RTK

uses a brushless DC motor to turn its propeller and generate thrust.

The servos are the two actuators connected through a servo connection mech-

anism to both ailerons. Damaged actuators can prevent the drone from flying

correctly and thus it is important to ensure their proper functioning.

servo connection

pitot probe

motor

mechanisms

To check the actuators, follow these steps:

1. The motor must be clean and spin smoothly without friction to function

151

Summary of Contents for EBEE RTK

Page 1: ...Extended User Manual eBee RTK Revision 3 December 2014 Copyright 2010 2015 senseFly Ltd ...

Page 14: ......

Page 71: ...Part II Advanced functionalities ...

Page 147: ...Part III Maintenance Repair and Troubleshooting ...

Page 182: ......

Page 183: ...Part IV Specifications ...