79

The compressors of the Line Compact are supplied from factory already tested and filled with mineral lubricant oil LUB SCHULZ or synthetic

lubricant oil SH-46 SYNTHETIC (Kluber).

1. INITIAL START PROCEDURE

A.

Check the oil level: the oil level sight must be covered;

B.

Power up the compressor (light 4 on the instrument panel must turn on);

C.

Close the valve of the service line;

D.

If light 4 is on, press the on (green) button to start the machine and, right after that, the off (red button), observing if the rotation direction

of the assembly is the same as of the arrow located on the air end, and if the rotation direction of the fan is correct (the correct air flow is

towards the radiator);

Note:

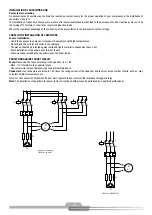

In case the direction is wrong, disconnect the compressor from the power supply and invert the wires in the input of the contactor K1

or in the output of the protection fuses and repeat the procedure D. For the fan, invert only the two (2) cables in contactor K5.

E.

After making sure the rotation direction is correct, close the side door and press the ON (green) button to put the compressor into opera-

tion, with the valve closed until the compressor reaches the maximum pressure.It will go into relief; open the valve slowly and your rotary

screw compressor will be ready to supply compressed air to the compressed air system.

12. START PROCEDURE

The Compressors are supplied from factory already tested and filled with synthetic lubricant oil LUB SCHULZ.

Before the initial start of the compressor, check: the retightening of the hoses of the hydraulic circuit and of

the electric contacts; turn on the dryer five minutes before the start of the compressor (when installed).

IMPORTANT

- Do not allow, at the first start, the motor to run for over 3 (three) seconds with the rotation inverted. The

operation of the item D is quick and easy to see. If there are difficulties in the start, refer to the chapter

Troubleshooting.

- In normal situations, use the OFF (red) key in the instrument panel, which will produce a timed relief before the complete turning off of

the compressor.

- The emergency button must only be used when a fast deactivation of the compressor is desired. Its use in normal conditions will cause

failure of the equipment which is not covered by the Warranty.

IMPORTANT