88

OCCASIONAL DEFECTS

PROBABLE CAUSES

SOLUTION

Current of the motor above the

rating operating current.

Rotation reversed.

Check the rotation direction.

Voltage below the specification.

Recheck the dimensioning of the cables.

Compressing assembly stuck.

Request the presence of the Technical Assistance.

Electric motor rotation decrea-

ses during start.

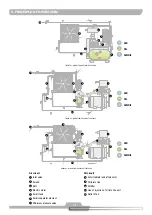

Commutation time of the star/delta switch too long

(analog compressor).

Set the time for 4 or 5 seconds by adjusting the second timer.

Admission valve open.

Check the cause.

Voltage drop in the power supply.

Check the installation.

Second timer or coil of contactors K2 and K3 defective.

Check if the timer is inverting the contact on the established

time.

Check if the coils of the contactors K2 and K3 are perfect and

receiving power.

O compressor

desliga e não volta a

ligar mesmo com a pressão

na rede baixa.

Overload relay tripped.

Check the current and setting of the overload relay.

High temperature.

Thermal protector went off.

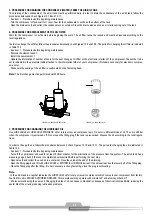

Check the oil level and refill it if necessary. Use LUB SCHULZ/

LUB SCHULZ SYNTHETIC oil for rotary screw air compressor.

Check if the fan is not broken (blades).

Replace the oil filter. The first change must be done after 300

hours of operation.

Check if there is air flow on the radiator. (Clean it if clogged).

Check if there is oil leak and fix it.

The compressor starts and

immediately turns off.

Lack of oil. The temperature rises quickly.

Check the oil level and refill it (Refer to chapter Preventive

Maintenance), using LUB SCHULZ/LUB SCHULZ SYNTHETIC oil

for rotary screw air compressor.

Air/oil separator element clogged.

Change the air/oil separator element and the oil, using LUB

SCHULZ/LUB SCHULZ SYNTHETIC oil for rotary screw air

compressor.

Compressor turns off and won’t

start even with the system

pressure low

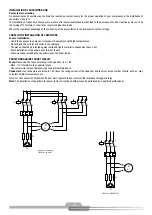

Phase missing on the command.

Look for the cause as per the electrical scheme.

Coil of the contactors burnout.

Coil of the relay of seconds KT2 or of the contactor K1 burnout.

Pressure switch unadjusted.

Compressor won’t turn off

after the time adjusted on

“KT3”, or turns off immediately

when button 2 is pressed (SRP

3010/3015/3015 ll/3020/3025/

3030 compact)

Timer defective.

Request the presence of the Technical Assistance.

The compressor suddenly lost

performance.

Pressure is too low in the air

system.

Note: Before any actions, read

the notes at the end of the trou-

bleshooting and on the display

of the Electronic Interface.

Belts loose or worn out.

Adjust the tension or replace the belts.

Air filter clogged.

Check the restriction indicator and the conditions of the air

filter, replacing it if necessary.

Hose that depressurizes the tank is disconnected from the admission

valve or broken. (Observe typical leak noise).

Connect the hose or replace it.

Relief valve stuck open. Compressor will not compress the full air flow

to the air system. Admission valve won’t open.

Request the presence of the Technical Assistance.

Coil of solenoid valve burnout or with hole clogged.

Pipe that feeds the solenoid valve broken or disconnected.

Pressure switch unadjusted (SRP 3010/3015/3015 ll/3020/3025/3030

Compact).

Air leak in some pipe of the compressor.

Compressor with load/relief

cycles too fast.

Air consumption too lower than the production of the compressor.

Turn off some compressor in parallel or install a larger tank.

Outlet valve closed.

(In this case, pressure is too low in the air system).

Open the valve slowly.

Great load loss close to the compressor.

Eliminate load loss.

Pressure switch with range too small

(SRP 3010/3015/3015 ll/3025 Compact)

Request the presence of the Technical Assistance.