85

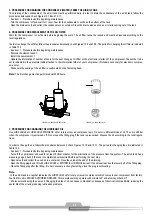

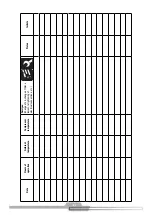

(1) Check the oil level when the compressor is off (wait until the air and oil are separated and the bubbles

(foam) are eliminated, since this may mask the oil level).

(2) The first time with 300 hours.

(4) On a quarterly basis or when required.

(5) Replace the filter if the indicator (if any) presents a restriction.

(6) The useful life of the separator element is up to 8,000 hours of service provided that all the following requirements are met:

- installation conditions according to items 1 and 2 in the Installation Chapter;

- Preventive maintenance performed correctly (according to its chapter);

- Infrequent machine operating regime (cycle load / relief).

Replacement period for the separator element must always be evaluated by the Technical Assistance that attends your screw compressor

(recommendations valid for factory supplied mineral oil as well as synthetic oil).

(7) Perform replacement of elements regularly to obtain maximum efficiency and quality of Schulz air filters, thus maintaining low opera-

ting costs. The filter elements must be changed at least once a year or when the pressure drop exceeds the recommended maximum of

0.6 bar.

(8) Operating conditions such as ambient temperature, air/oil radiator obstruction by contamination, machinery room air renewal, cleaning

of air, oil and separator element filters, can cause the unit’s discharge temperature at levels that alter the useful life of the oil.

When operating conditions regularly cause the compressor unit’s discharge temperature below 90°C, the oil change period must meet

the following:

- If mineral oil – every 1,000 hours;

- If semi-synthetic oil – every 4,000 hours;

- If synthetic oil – every 8,000 hours.

When operating conditions regularly cause the compressor unit’s discharge temperature above 90°C, the oil change period must meet

the following:

- If mineral oil 1,000 – every 500 hours;

- If mineral oil 4,000 – every 2,000 hours;

(9) Included in mineral oils: Lubschulz mineral 1,000 and Lubschulz mineral 4,000.

(11) Operating conditions such as: ambient temperature, air/oil radiator obstruction by contamination, machinery room air renewal, clea-

ning of air, oil and separator element filters can promote/accelerate wear of nylon tubing.

IMPORTANT