III - 53

3

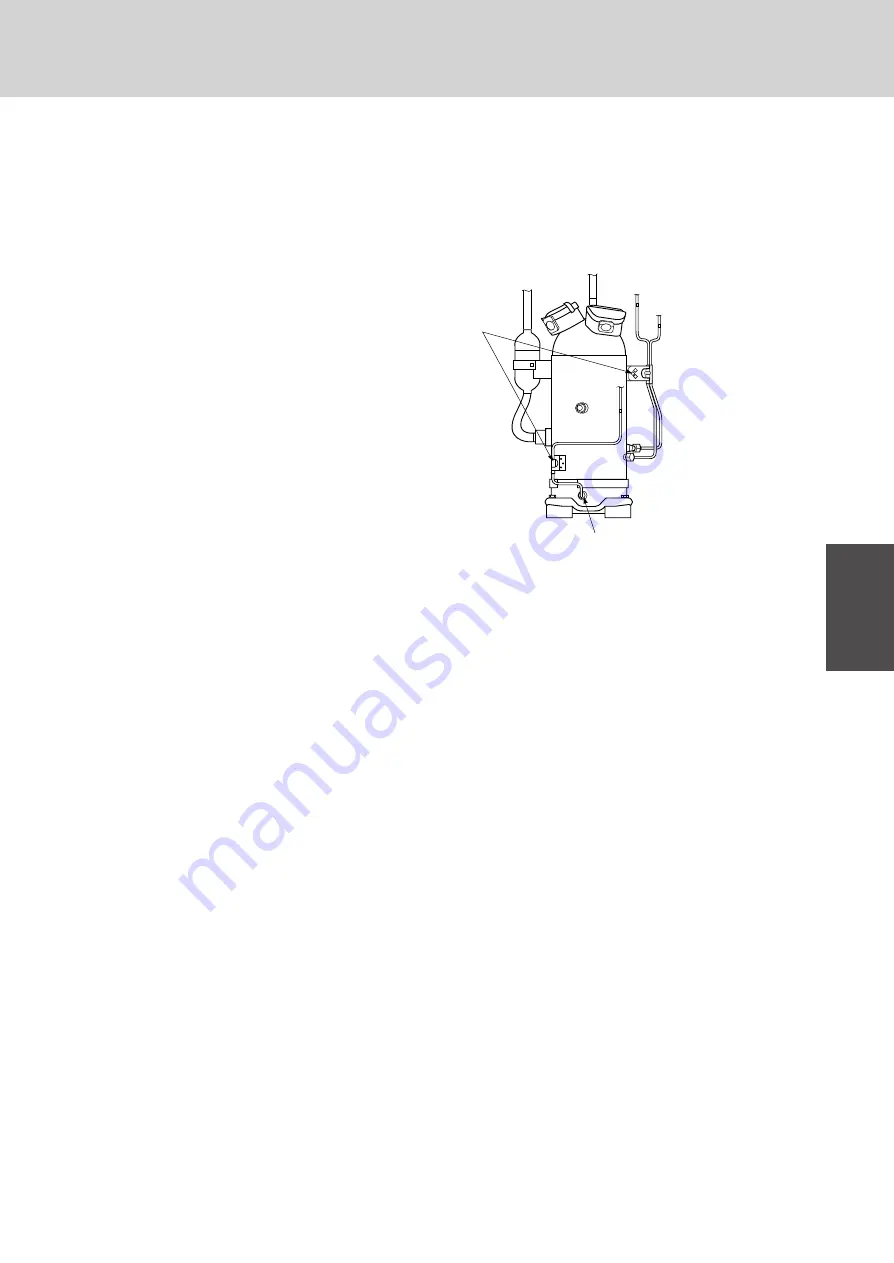

SM830052

Service Procedures

Installation:

(1)

Installation preparations

¶

Remove the rubber plug and intake pipe cap (welding) from the new compressor.

¶

Disconnect the pipe holding fixtures, flared pipes and unions (for compressor with power save).

¶

Install the parts removed from the old compressor on the new compressor. (Install in the same state as the

original state.)

For a compressor with power save, tilt so that there are no oil leaks from the new and old compressors, and

install the A section flared pipe and union. Always wrap the unions with sealing tape.

(2)

Install the crank case heater on the compressor.

(3)

Put the compressor rubber cushion on the prescribed position of the bottom plate.

(4)

Set the compressor on the unit. The left side is the compressor with power save. (Install in the same state as the

original state.)

(5)

Form the pipes and insert in the welding location.

(6)

Replace the internal nitrogen and attach the copper port at each section.

(7)

Raise the air-tight test pressure to 2.94 MPa (30 kg/cm

2

G) with nitrogen and check that there are no leaks.

(8)

When you install the removed parts, also install the electrical component box in its original state.

(9)

After completing the air-tight test, reduce the vacuum pressure in the indoor/outdoor units and pipes to 133 Pa (1

mmHg).

(10) After establishing the vacuum, charge with refrigerant.

Charge the sum of the “factory refrigerant amount” and “additional charging refrigerant amount” which are

mentioned on the nameplate and the CAUTION label.

(11) This completes the compressor replacement.

7. Operation Procedure for Replacing the Compressor

0352_C_I

A

Pipe holding

fixtures