17

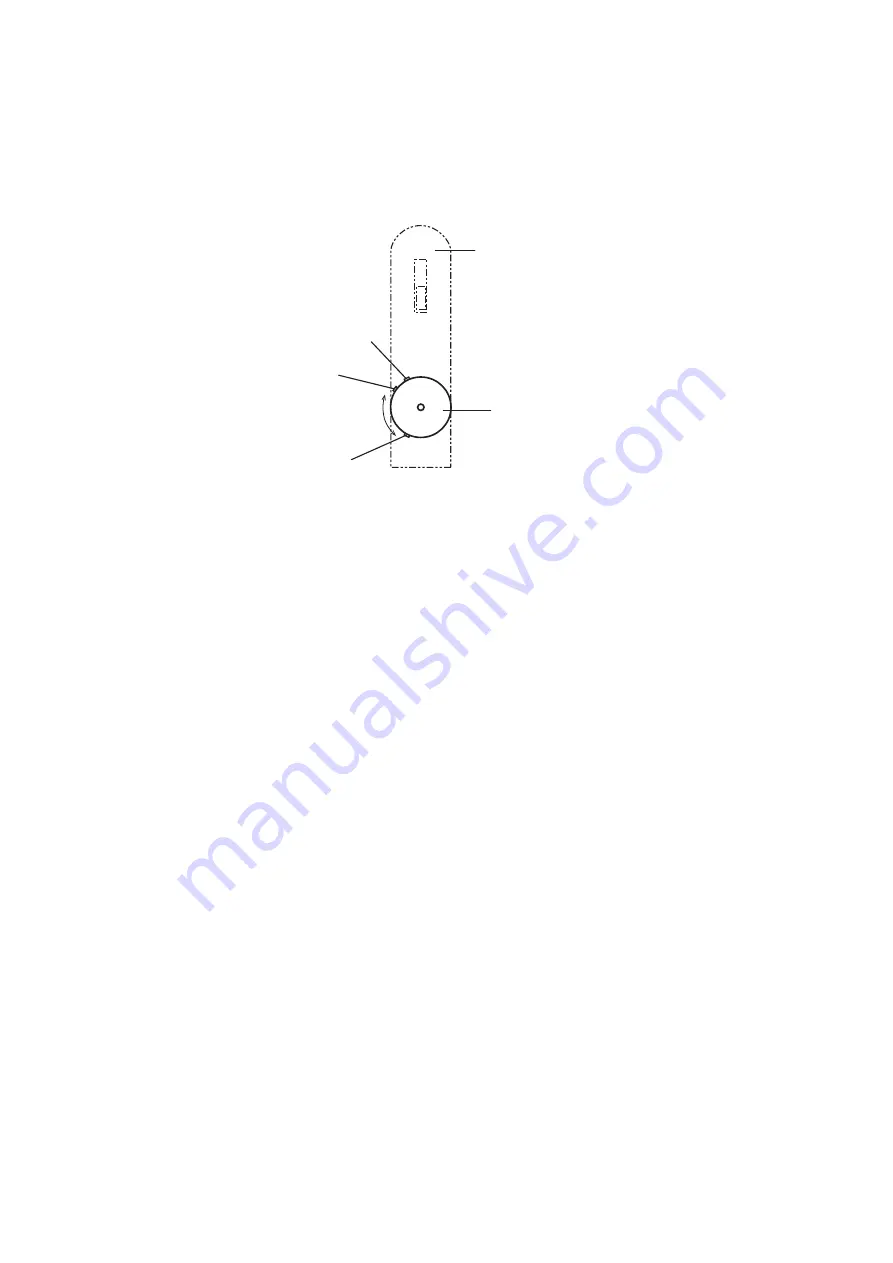

Adjust airflow rate by turning the airflow control valve in the range MIN position to

MAX position shown in Figure 9. Turning it over MAX position to STOP position

reduces the airflow rate due to valve structure.

3. HOW TO POLISH A WORK PIECE WITH THE FLEXIBLE POLISHING PAD

When the polisher rotation gets stable after the start, begin the polishing operation, Put

the flexible polishing pad slowly on the face to be polished when it comes in touch with

a work piece. Too much force to the pad would damage the work piece and cause

quick worn-out of the pad, and would not be an efficient polishing.

The efficient polishing depends on many elements, characteristics of work piece, the

flexible polishing pad, pressure between the flexible polishing pad and work piece, water

flow rate, skill of operator and polisher speed.

The operator would have an experience of optimum water flow rate. Contact of polisher

speed is utilized by airflow control value ( see Figure 1, page 6 ) The optimum polishing

speed, therefore, could not be specified in this instruction manual due to too many

elements.

Relation of r/min and compressed air pressure is shown in Figure 5 in page 8. The

operator would have an experience of optimum polisher speed.

4. CAUTIONS IMMEDIATELY AFTER USE

After the polishing operation, turn OFF the switch lever and place the polisher on floor

ensuring that its rotation is completely stopped. Failure to do so could cause accidents.

Inordinate impact to the polisher body could result in tear or crack of the polisher and

the flexible polishing pad. Handle them with good care.

Switch Lever

Stop

Max.

Min.

Airflow Control Valve

Figure 9 Airflow Control Valve

Summary of Contents for PA-2

Page 2: ......