1. Specification

1-7

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

1.4.2 Media Type & Condition

¾

Special Paper

: Finisher must be able to handle special types of papers such as Tab, Archive,

Transparencies, etc (See 1.4.3). A slight underperformance is tolerable for special

papers, however it must not damage the paper in any case.

¾

Static

: All static must be controlled so that it would not harm the quality of the stack. Users must never

be shocked by static from the finisher body or finisher’s any module.

¾

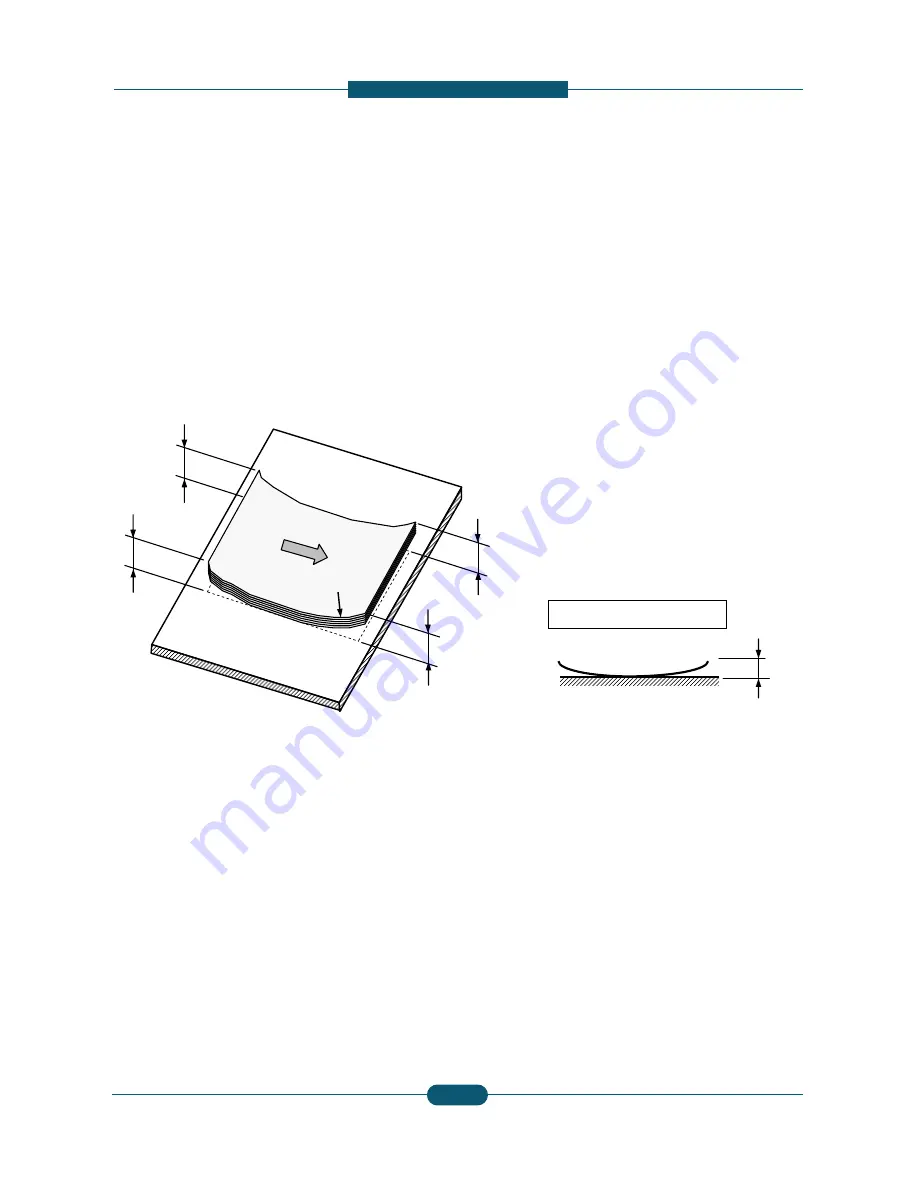

Curl

: Finisher shall handle

±

1/2” curled output as delivered from the IOT.

A1(mm)

A2(mm)

A4(mm)

A3(mm)

Feeding Direction

Radius(R)

10 sheets

Glass

A

A = MAX (A1,A2,A3,A4)

[‘Curl’ measuring method]

¾

Skew

: Finisher must be able to control ‘skew’ of the sheet received from the IOT. The skew must be

less than 1% of the length of the paper received from IOT main body (feeding direction).