11

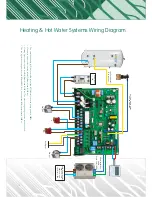

Heating & Hot Water Systems

H

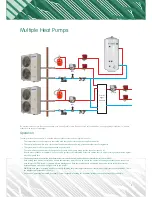

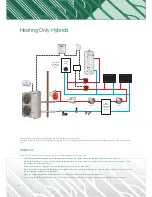

Pump HP

Pump Z1

HW

Z2

Z1

Low Loss

Header,

Buffer Tank,

or Heat

Exchanger

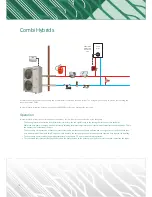

Reduced Glycol System

If the amount of glycol in the system is an issue and you want to reduce the amount then this can be done with a plate heat exchanger. This will need to be

correctly sized for the duty and the flow and return temperatures of the system.

Two circulation pumps will also be needed for this setup with one on each side.

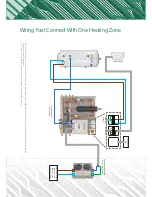

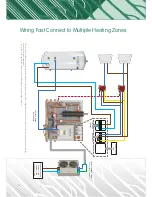

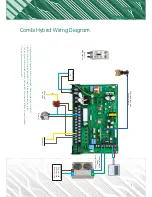

Operation

• The temperature of the hot water is controlled with the cylinder sensor and the supplied controller.

• The controller has a built in time clock control and has both daily and weekly sterilisation functions for legionella.

• The system is able to be setup as open vented or pressurised.

• The coil within the cylinder must be designed for use with a heat pump with a surface area of at least 2.5 m².

• A guideline for sizing the cylinder would allow 55 litres of water per person each day.

• It is recommended that the heat pump is sized so that it is able to reheat the cylinder within an hour.

• As with most cylinders, it is possible to connect a PV system to the immersion heaters to reduce costs. A battery storage system is also a great

way to help with this.

• The heating system is controlled via a thermostat / time clock that is wired back to the internal control board (MIM).

• There is not a limitation to the number of heating zones that can be connected to this setup.

• This setup shows two heating zones with pumps two and three.

• Each heating zone will be controlled by its own thermostat or timer, this will operate it’s own zone valve which will then control the pump. This

in turn will create the run signal for the heat pump to operate in heating mode.

• Whilst the heat pump is running, it will be constantly adjusting the water temperature to suit the ambient temperatures and conditions. This is

the weather compensation of the unit.

• The use of a hydraulic separator is recommended as this will help to make the installation and commissioning a lot smoother.