Operating manual - ChillPAC and LP ChillPAC Mk 3

010823 en 2021.06

39/68

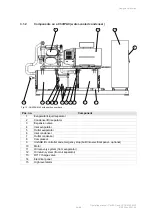

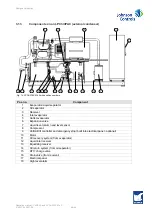

4.3.5

ChillPAC with variable speed drive (VSD)

ChillPAC with a reciprocating compressor is available with:

•

fixed speed

•

variable speed drive (VSD)

A reciprocating compressor where the motor drive speed is controlled by a frequency converter is also

called a RecipRota compressor in UniSAB terminology. See the UniSAB III Engineering manual for fur-

ther description.

For some ChillPAC models with reciprocating compressors, mechanical vibrations caused by resonance

may occur in the actual operating range 700-1500 rpm. This will in some cases result in an increased vi-

bration level over an interval of approximately 100-150 rpm. As a rule of thumb, the rpm area is skipped

if the vibration level exceeds the recommended maximum vibration level (see the compressor manual).

All ChillPACs are tested from factory. If skipping of rpm is required, this has been done and noted in the

setting list (wirring diagrams).

It is recommended to check the vibration level during pre-start. The resonance rpm area may change

after shipping and installation.

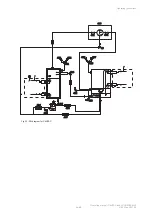

4.4

Secondary system

4.4.1

General information

Designing a secondary system is a complex task where many things must be considered, for instance:

•

load variations

•

pressure loss

•

service

•

maintenance

•

corrosion and erosion

•

fouling.

Note:

Rapid temperature variations in the secondary system can damage the chiller. It is recommended

to keep temperature changes below 1 K/min. Install a buffer tank or balancing tank to avoid great varia-

tions in load and temperature. Avoid fluctuating pressure and temperature as this can damage the heat

exchangers.

4.4.2

Cleaning in place

It is recommended to install valves and connections for chemical cleaning of open secondary circuits.

ChillPAC evaporators and condensers are fully welded heat exchangers and

cannot

be cleaned

mechanically.

For more information about chemical cleaning, please contact a Johnson Controls representative.

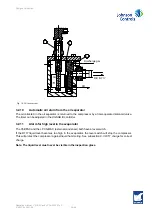

4.4.3

Temperature and flow control

The UniSAB III controller adjusts the compressor load by means of input from a PT100 temperature sen-

sor. A sensor threaded branch and sensor pocket are delivered with the unit. The sensor must be fitted

into the evaporator outlet pipe minimum 1 metre away from the evaporator.

4.4.4

Water and brine treatment

Brine and water for industrial refrigeration plants often contain impurities that can create a coating (foul-

ing) on the heat transferring surfaces. This reduces the heat transmission and in some cases the coating

causes corrosion of the heat transferring surfaces.