Operating manual - ChillPAC and LP ChillPAC Mk 3

34/68

010823 en 2021.06

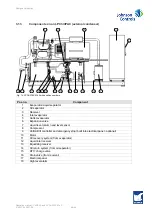

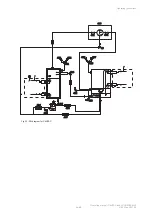

3.2.9

Automatic oil recovery system from evaporator

The relatively small amount of oil leaving the compressor and oil separator with the discharge gas is

gradually collected at the bottom of the evaporator.

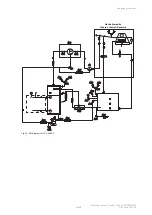

An oil recovery pot, Fig. 19, is connected to the evaporator by a pipe. From the recovery pot, the oil is

automatically returned to the compressor.

A float is fitted in the oil recovery pot, pos. 9, Fig. 18. It has the exact density which allows it to float on

the collected oil and sink in R717.

The float has a built-in reed switch which activates the solenoid valve, pos. 8 in Fig. 18, in the oil return

line to the compressor and the solenoid valve, pos. 7 in Fig. 18, on the hot gas line. The oil is led directly

to the compressor suction side, driven by the pressure difference between the LP and HP sides.

The oil pot has an integrated piston which is driven by the discharge gas. The piston closes the connec-

tion to the evaporator during the oil recovery cycle.

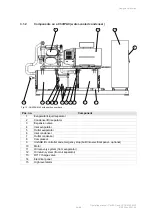

Fig. 18: System for reciprocating compressor

Pos. no.

Component

1

Compressor

2

Evaporator

3

Level float switch

4

Stop valve

5

Stop valve

6

Stop valve

7

Solenoid valve combined with filter and stop function

8

Solenoid valve combined with filter and stop function

9

Oil recovery pot

10

Discharge gas line

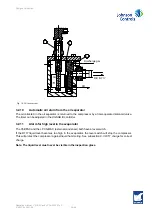

When the oil level in the recovery pot, Fig. 19, is high, the float switch, pos. 1, is activated. The switch

turns on the solenoid valve in the oil recovery system. Incoming discharge gas pushes down the piston,

pos. 3, which blocks the oil drain inlet port. Discharge gas is led into the oil reservoir through the small

nozzle, pos. 2. The rising pressure forces the oil back into the suction side of the compressor.

To ensure proper functioning, a timer delays the off-signal from the float switch for a few seconds.

Note:

As shown in Fig. 19, the float ball must be positioned with NO facing upwards.

For further information about the oil recovery pot, see chapter