Operating manual - ChillPAC and LP ChillPAC Mk 3

30/68

010823 en 2021.06

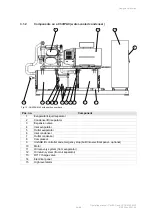

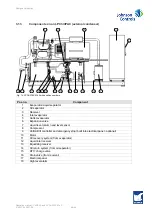

3.2

Main components

3.2.1

Compressor

The compressor is a Johnson Controls Denmark standard compressor, complete with stop valves, mo-

tor, etc. For further information, see the compressor operating manual.

ChillPAC is equipped with an oil separator which is integrated in the condenser. LP ChillPAC (external

condenser) is equipped with a standard oil separator.

3.2.2

Control system

Chillers are delivered with UniSAB III monitoring, safety and capacity regulating system.

The control system is described in the UniSAB III manual.

A UniSAB III setting list for each specific order is enclosed with the manual.

If the actual operating conditions are different from the design conditions, the settings must be checked.

VSD settings are stated in the wiring diagrams.

Note:

Changes in factory settings must only be carried out by competent personnel.

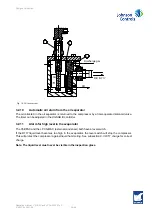

3.2.3

Evaporator

The evaporator is a fully welded plate heat exchanger where plates are welded together into cassettes.

R717 evaporates between the two welded plates which make up the cassettes and water/brine is cooled

in the channels inside the cassettes. The R717 droplets are separated from the vapour in the separator

room above the plates.

The evaporator has one or two sets of brine connections depending on size and operating conditions.

A sight glass is mounted at the end cover.

Note:

The liquid level must never be visible in the inspection glass. See subsection

and the P&I diagram for correct charge.

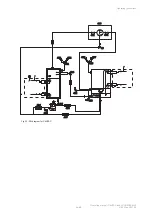

3.2.4

Condenser

The ChillPAC is equipped with a water-cooled condenser. The condenser is a fully welded plate heat ex-

changer where plates are welded together into cassettes.

R717 condenses between the welded plates which make up the cassettes and cooling water circulates

in the channels between the cassettes.

The liquid expansion system is based on a high pressure regulating system which is built into the bottom

of the condenser.

The oil separator is integrated in the condenser shell. Before the discharge gas enters the condenser

cassettes, the main part of the oil is separated from the discharge gas and returned to the compressor.